5 Fascinating Facts About Surface Mount Technology

Surface mount technology has revolutionized electronics manufacturing by enabling the direct placement of components onto the surface of printed circuit boards. This method optimizes space, allowing for the creation of compact and multifunctional devices. Automation in SMT assembly ensures consistent quality and reduces manual labor, making it a cornerstone of modern production lines. By enhancing efficiency and lowering costs, SMT has become indispensable in industries like consumer electronics, where smaller form factors and faster production cycles are critical. Its impact extends across telecommunications, automotive, and other high-tech sectors, driving innovation and reliability.

Key Takeaways

Surface Mount Technology (SMT) enables the miniaturization of electronic devices, allowing for the creation of compact and multifunctional products essential in today's tech-driven world.

Automation in SMT assembly enhances precision and reduces human error, leading to consistent quality and faster production cycles, which are crucial for meeting market demands.

SMT supports the integration of ultra-miniature components, significantly lowering manufacturing costs by optimizing material usage and reducing labor expenses.

Advanced soldering techniques in SMT ensure strong electrical and mechanical connections, enhancing the durability and reliability of devices in challenging environments.

The flexibility of SMT allows for innovative designs, such as flexible PCBs and 3D assembly techniques, which are vital for the development of modern technologies like AI and 5G.

By leveraging SMT, manufacturers can produce high-performance devices that meet the rigorous demands of various industries, from telecommunications to automotive.

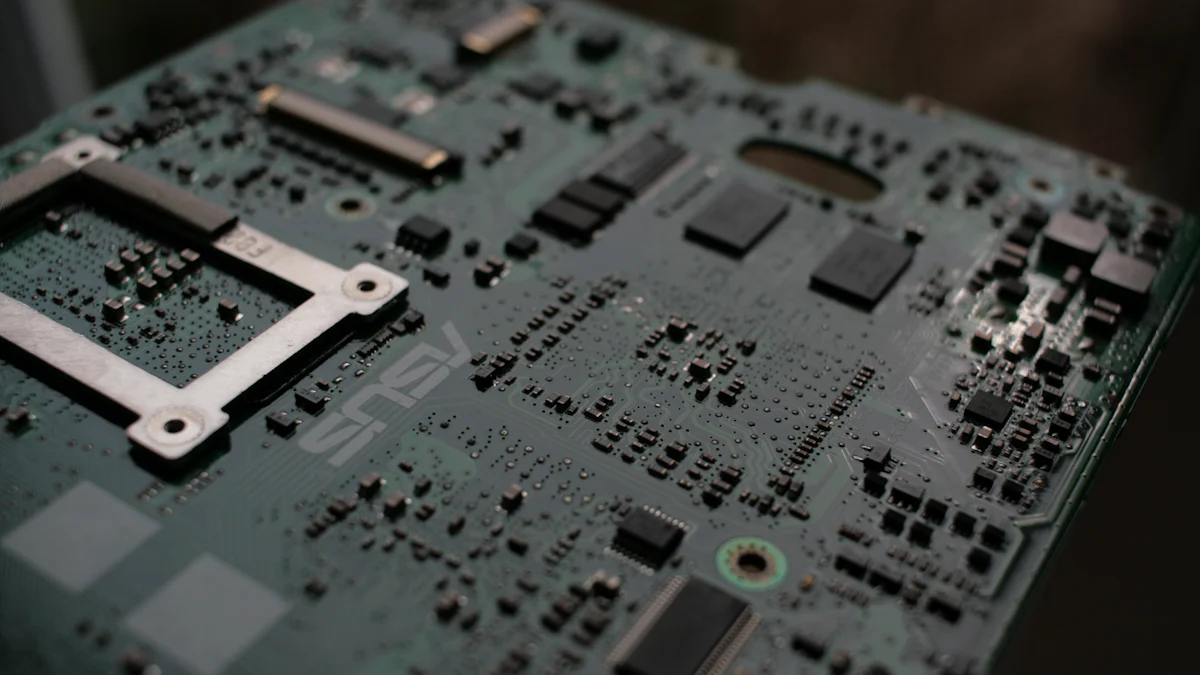

Surface Mount Technology Enables Miniaturization

Surface mount technology has become a driving force behind the miniaturization of electronic devices. By allowing components to be mounted directly onto the surface of printed circuit boards, it optimizes space utilization and supports the creation of smaller, more efficient products. This innovation has transformed industries, enabling manufacturers to meet the growing demand for compact and high-performance devices.

Smaller and More Efficient Components

The evolution of surface mount technology has paved the way for ultra-miniature components. These components, designed for high-density assembly, reduce the overall size of electronic devices without compromising functionality. For instance, SMT supports the integration of resistors, capacitors, and microprocessors into smaller footprints, which enhances product performance while conserving space.

Scientific Research Findings: A study on the "Global Surface Mount Technology Market Size and Growth Rate" highlights that the increasing demand for miniaturized electronics has significantly driven the adoption of SMT, with the market projected to grow at a CAGR of 5.8% from 2023 to 2030.

This capability has proven essential in industries like telecommunications and consumer electronics, where compact designs are critical. Devices such as smartphones, wearables, and IoT gadgets rely on SMT to achieve their sleek and portable forms. The ability to produce smaller components also reduces material usage, contributing to cost efficiency and sustainability in manufacturing.

The Role of SMT in Portable and Multifunctional Devices

Surface mount technology plays a pivotal role in the development of portable and multifunctional devices. By enabling the assembly of high-density circuits, SMT allows manufacturers to incorporate multiple features into a single device. For example, modern smartphones combine communication, photography, and computing capabilities within a compact design, made possible by SMT's precision and efficiency.

Scientific Research Findings: According to the study "SMT Supports Ultra-Miniature Components," advancements in SMT assembly techniques have enabled the production of lighter and more powerful devices, meeting the demands of modern consumers.

Additionally, SMT supports flexible PCB designs, which are crucial for wearable technology and other innovative applications. These flexible circuits enhance durability and adaptability, ensuring reliable performance in various environments. The ability to integrate diverse functionalities into compact devices has revolutionized industries ranging from healthcare to automotive, where portability and efficiency are paramount.

Surface Mount Technology Delivers Precision in Assembly

Precision plays a vital role in the success of modern electronics manufacturing. Surface mount technology ensures high levels of accuracy during assembly, which is essential for producing reliable and efficient devices. By leveraging advanced machinery and techniques, SMT has set a new standard for precision in the industry.

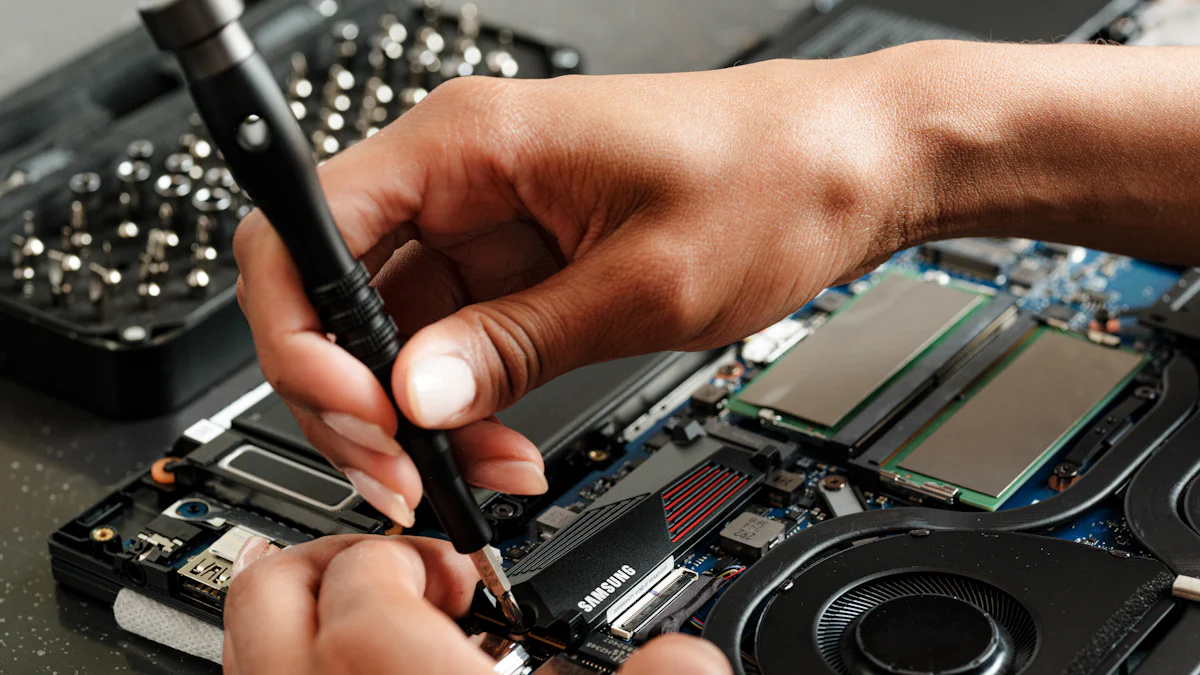

Automated Component Placement for Accuracy

Automated component placement forms the backbone of SMT assembly. Machines equipped with sophisticated vision systems and robotic arms place components onto printed circuit boards with remarkable accuracy. This automation eliminates human errors, ensuring consistent quality across production batches.

Key Insight: Compared to traditional through-hole methods, SMT assembly relies heavily on automation, which significantly reduces defects and enhances reliability.

The use of automated systems also enables manufacturers to handle components of varying sizes, from ultra-miniature resistors to larger integrated circuits. These machines operate at high speeds, allowing for faster production cycles without compromising precision. This capability proves invaluable in industries like telecommunications and automotive, where even minor inaccuracies can lead to significant performance issues.

Advanced Soldering Techniques for Strong Connections

Soldering techniques in SMT assembly have evolved to ensure robust and durable connections. Reflow soldering, a widely used method, involves heating solder paste to create secure bonds between components and the PCB. This process guarantees strong electrical and mechanical connections, which are critical for device reliability.

Comparative Advantage: Unlike traditional assembly methods, SMT's advanced soldering techniques enhance electrical performance and reduce the risk of connection failures.

Modern soldering equipment incorporates temperature control systems to prevent overheating, which could damage sensitive components. These advancements support the production of high-quality PCBs that meet the demands of high-frequency applications. Strong solder joints also improve resistance to mechanical stress, making SMT-assembled devices more durable in challenging environments.

Surface Mount Technology Boosts Manufacturing Efficiency

Surface mount technology has redefined manufacturing efficiency in the electronics industry. By leveraging advanced automation, manufacturers achieve faster production cycles and optimize resources, ensuring cost-effectiveness and high-quality output. This approach has become a cornerstone for modern production lines, enabling businesses to meet growing demands while maintaining competitive pricing.

Faster Production Through Automation

Automation plays a pivotal role in enhancing the speed of SMT assembly. Machines equipped with cutting-edge technologies, such as artificial intelligence (AI) and machine learning (ML), place components on printed circuit boards with remarkable precision and speed. These systems significantly reduce manual labor, allowing manufacturers to produce large volumes of electronic devices in shorter timeframes.

Key Insight: Automated SMT processes can handle ultra-miniature components and complex designs, accelerating production rates while maintaining consistent quality.

The integration of automation also minimizes human error, which often leads to defects in traditional assembly methods. By eliminating these errors, SMT ensures reliable performance and reduces the need for rework, saving both time and resources. Industries like telecommunications and automotive benefit greatly from this efficiency, as they require high production throughput to meet market demands.

Cost-Effectiveness and Resource Optimization

Surface mount technology offers unparalleled cost-effectiveness by reducing labor costs and optimizing material usage. Automation eliminates the need for extensive manual intervention, cutting down on workforce expenses. Additionally, SMT's ability to handle smaller components reduces material costs, as these components require less raw material for production.

Statistical Data: Studies indicate that SMT assembly processes can lower manufacturing costs by up to 30% compared to traditional through-hole methods, thanks to reduced labor and material expenses.

Resource optimization further enhances the cost-effectiveness of SMT. The technology maximizes the use of PCB space, enabling the production of compact and multifunctional devices. This efficient use of resources not only lowers production costs but also supports sustainability efforts by minimizing material wastage. Manufacturers in Huizhou Zhongkai High-tech Zone and other innovation hubs leverage these benefits to remain competitive in the global market.

Key Insight: While initial setup costs for SMT equipment may be high, the long-term savings in labor and materials make it a highly economical choice for large-scale production.

By combining faster production cycles with cost-effective practices, surface mount technology empowers manufacturers to deliver high-quality products at reduced costs. This efficiency ensures that businesses can adapt to evolving consumer demands and maintain profitability in a competitive landscape.

Surface Mount Technology Enhances Reliability and Performance

Surface mount technology has set a benchmark for reliability and performance in modern electronics. Its advanced assembly techniques ensure that devices can withstand mechanical stress and deliver exceptional electrical performance, even in demanding applications.

Durability and Resistance to Mechanical Stress

Devices assembled using surface mount technology exhibit remarkable durability. The direct placement of components onto printed circuit boards creates strong mechanical bonds, reducing the risk of dislodgment during operation. This feature proves essential in industries like automotive and aerospace, where devices often face vibrations and physical shocks.

Reflow soldering, a key process in SMT, enhances the mechanical strength of connections. By heating solder paste to precise temperatures, manufacturers achieve robust joints that resist wear and tear. These strong connections ensure that devices maintain functionality even under challenging conditions.

Scientific Research Findings: Studies emphasize the importance of thermal management and stress resistance in SMT. The coefficient of thermal expansion (CTE) helps manufacturers predict and mitigate the impact of temperature changes on PCB durability.

The compact design of SMT-assembled devices also contributes to their resilience. Smaller components reduce the overall weight of the device, minimizing the strain on solder joints. This combination of lightweight design and strong connections makes SMT a preferred choice for applications requiring high reliability.

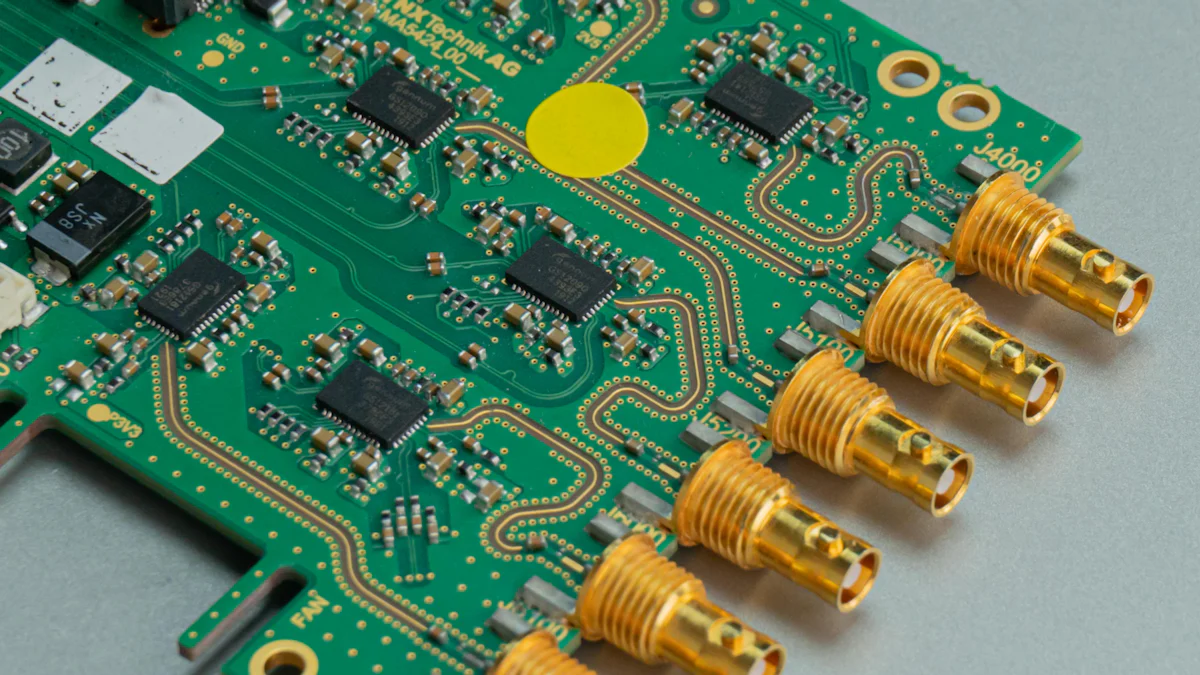

Improved Electrical Performance for High-Frequency Applications

Surface mount technology excels in high-frequency applications, where electrical performance is critical. The planar design of SMT components minimizes signal interference, ensuring efficient transmission of high-frequency signals. This capability supports industries like telecommunications, where devices must handle complex data at rapid speeds.

Scientific Research Findings: Research highlights factors such as impedance of package signal lines and cross-talk noise as key considerations for high-frequency applications. SMT addresses these challenges by optimizing the layout of components on the PCB.

Advanced soldering techniques in SMT further enhance electrical performance. Reflow soldering creates low-resistance connections, improving signal integrity and reducing energy loss. These strong electrical bonds enable devices to operate efficiently in high-frequency environments.

Thermal management plays a crucial role in maintaining performance. SMT's compact design allows for effective heat dissipation, preventing overheating in high-frequency circuits. This feature ensures that devices remain reliable even during prolonged use.

Manufacturers in innovation hubs like Huizhou Zhongkai High-tech Zone leverage SMT's capabilities to produce cutting-edge devices. By combining durability with superior electrical performance, surface mount technology continues to drive advancements in modern electronics.

Surface Mount Technology Drives Innovation in Electronics

Surface mount technology continues to push the boundaries of innovation in electronics manufacturing. By enabling advanced techniques and supporting emerging technologies, it plays a pivotal role in shaping the future of the industry.

Flexible PCBs and 3D Assembly Techniques

The integration of flexible printed circuit boards (PCBs) into electronic devices has unlocked new possibilities for design and functionality. Flexible PCBs, made using innovative materials like flexible substrates and conductive inks, allow manufacturers to create lighter and more durable devices. These materials also contribute to energy efficiency, aligning with sustainability goals in modern manufacturing.

Key Insight: Flexible PCBs enhance durability and adaptability, making them ideal for applications in wearable technology, automotive systems, and medical devices.

Surface mount technology complements these advancements by enabling precise assembly on flexible circuits. This capability ensures reliable performance even in devices exposed to bending or twisting. Additionally, SMT supports 3D assembly techniques, which involve stacking components vertically to maximize space utilization. This approach proves invaluable in creating compact, multi-layered circuit boards for high-performance applications.

The adoption of 3D printing in PCB production further enhances these capabilities. Manufacturers can fabricate intricate, multi-layered designs with precision and speed, streamlining the prototyping and production processes. This combination of SMT and 3D printing accelerates innovation, allowing companies to bring cutting-edge products to market faster.

Supporting Emerging Technologies Like AI and 5G

Surface mount technology serves as a cornerstone for the development of emerging technologies such as artificial intelligence (AI) and 5G. Its precision and efficiency enable the production of advanced components like AI chips and processors, which are essential for powering intelligent systems. In the automotive sector, for instance, AI-driven technologies rely on SMT to deliver reliable and high-performance electronic assemblies.

Scientific Research Findings: Leveraging AI in PCB design and manufacturing optimizes circuit layouts, identifies defects, and improves production workflows. This integration enhances efficiency and reduces errors in SMT processes.

The rise of 5G technology demands devices capable of handling high-frequency signals with minimal interference. SMT addresses this challenge by supporting the assembly of components with superior electrical performance. Its ability to create compact and efficient designs ensures that 5G devices meet the rigorous demands of modern telecommunications.

Manufacturers in innovation hubs like Huizhou Zhongkai High-tech Zone harness these capabilities to stay at the forefront of technological advancements. By combining SMT with AI-driven tools and sustainable practices, they contribute to a more eco-friendly and efficient future for electronics manufacturing.

Surface mount technology has become a cornerstone of modern electronics, driving advancements in miniaturization, precision, and efficiency. Its ability to accommodate ultra-miniature components and intricate designs has revolutionized the production of compact and high-performance devices. By enabling faster production cycles and reducing material wastage, it ensures cost-effective manufacturing while maintaining superior reliability. As industries continue to innovate with technologies like AI and 5G, surface mount technology remains pivotal in shaping the future of electronics. Manufacturers in innovation hubs like Huizhou Zhongkai High-tech Zone leverage its capabilities to stay competitive in a rapidly evolving market.

See Also

Transforming Semiconductor Displays: Zhongkai's Major Investment and Expansion

Discovering the Leading Tech Companies in Huizhou Zhongkai

Innovative Advances Emerging from Huizhou Zhongkai High-tech Zone

Three Leading Innovators Shaping Huizhou Zhongkai's Future

Exploring Zhongkai High-tech Zone: Ten Years of Energy Innovation

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271