Ball Grid Array vs Other SMT Options for High-Performance Applications

Ball grid array technology stands out among surface mount options due to its unique design and performance benefits. Unlike traditional SMT packages, BGA uses solder balls instead of pins, enabling higher pin density and improved electrical properties. This design enhances thermal conductivity and mechanical stability, making it ideal for high-performance applications. BGA packages also excel in heat dissipation and signal integrity, ensuring reliable operation in demanding environments. These characteristics make BGA a preferred choice for housing microprocessors and other components requiring efficient space utilization and superior electronic performance.

Key Takeaways

BGA technology offers superior electrical performance and thermal management, making it ideal for high-speed and high-density applications.

The compact design of BGA packages allows for higher pin density, which is essential for modern electronics like microprocessors and 5G systems.

BGA excels in reliability, particularly in harsh environments, due to its robust mechanical support and efficient heat dissipation.

While BGA provides numerous advantages, it may come with higher costs and complexity compared to simpler SMT options like QFP and SOIC.

Choosing BGA is beneficial for applications requiring advanced performance, while alternatives may be more suitable for cost-sensitive or low-pin-count designs.

Understanding the specific needs of your application is crucial for selecting the right SMT technology, ensuring optimal performance and cost-efficiency.

Understanding Ball Grid Array (BGA)

Definition and Structure

The Ball Grid Array (BGA) represents a modern surface mount technology designed to enhance the performance and reliability of electronic devices. Unlike traditional packages, BGA uses an array of small solder balls located on the underside of the integrated circuit (IC). These solder balls serve as both electrical and mechanical connections between the IC and the printed circuit board (PCB). This unique structure eliminates the need for pins or leads, resulting in a more compact and efficient design.

The solder balls in a BGA package are arranged in a grid-like pattern, which allows for higher interconnect density compared to older packaging methods. This configuration not only saves space but also improves electrical conductivity. The shorter connections between the silicon die and the PCB reduce signal interference and enhance overall performance. This structural innovation has made BGA a preferred choice for high-density and high-speed applications.

Key Features

BGA packages offer several key features that set them apart from other surface mount technologies:

High Interconnect Density: The grid arrangement of solder balls enables a higher number of connections within a smaller footprint, making BGA ideal for compact devices.

Improved Thermal Management: The design facilitates efficient heat dissipation, ensuring stable operation even in high-performance systems.

Enhanced Electrical Performance: Shorter connections reduce resistance and inductance, leading to faster signal transmission and better reliability.

Mechanical Stability: The solder balls provide robust mechanical support, reducing the risk of damage during operation or handling.

Compact Form Factor: The absence of leads and the efficient use of space make BGA packages suitable for modern miniaturized electronics.

Ease of Automation: The design simplifies the manufacturing process, allowing for precise placement and soldering during automated assembly.

These features collectively contribute to the growing popularity of BGA in the electronics industry, particularly for applications requiring high performance and reliability.

Applications in High-Performance Electronics

The versatility and efficiency of BGA packages make them indispensable in high-performance electronics. They are widely used in applications where space, speed, and thermal management are critical. Some notable examples include:

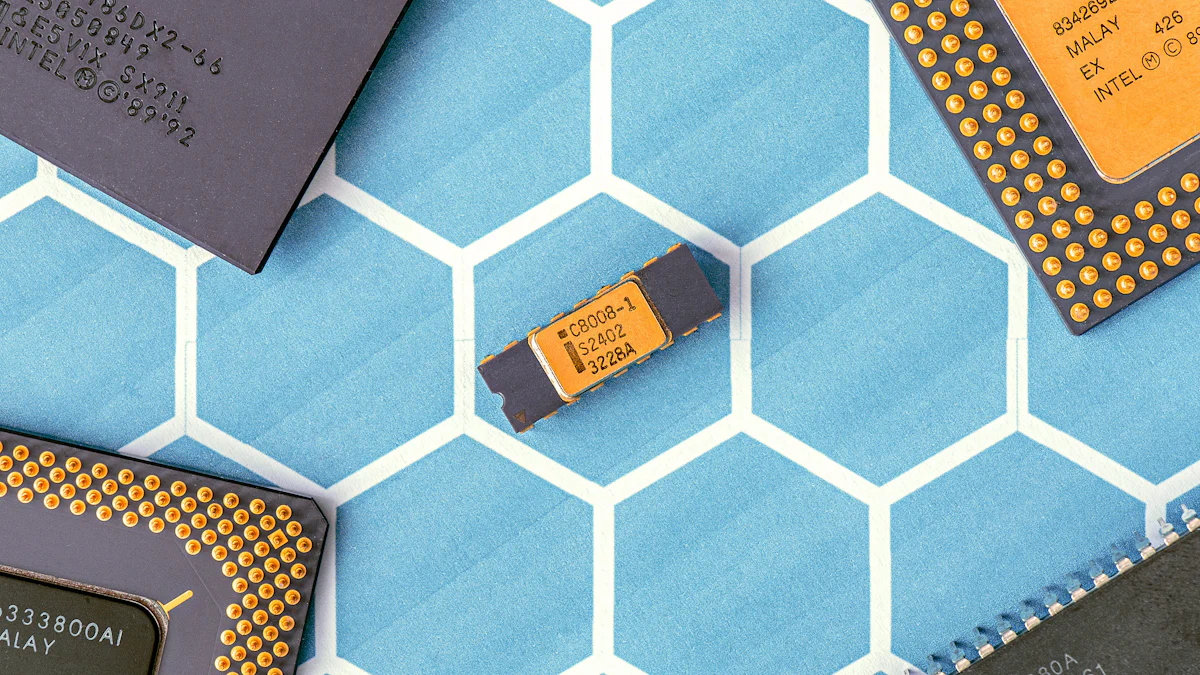

Microprocessors and Memory Chips: BGA packages are commonly used to house CPUs and memory modules due to their ability to handle high pin counts and dissipate heat effectively.

5G Base Stations: The high-speed and high-density requirements of 5G infrastructure make BGA an ideal choice for these systems.

Embedded Systems: Devices like industrial controllers and automotive electronics benefit from the compact size and reliable performance of BGA packages.

Consumer Electronics: Smartphones, tablets, and laptops rely on BGA technology to achieve sleek designs without compromising functionality.

High-Density Interconnect Applications: Advanced devices requiring dense interconnections, such as GPUs and AI processors, leverage the advantages of BGA packaging.

The adoption of BGA in these areas highlights its role in driving innovation and meeting the demands of modern electronic systems.

Overview of Other Surface Mount Technologies

Quad Flat Package (QFP)

The Quad Flat Package (QFP) is a widely used surface mount technology known for its rectangular or square shape with leads extending from all four sides. These leads, often referred to as gull-wing leads, provide reliable electrical connections to the printed circuit board (PCB). QFP packages are available in various sizes and pin counts, making them versatile for different applications.

QFP excels in applications requiring moderate pin density and compact designs. Its lead configuration allows for easy inspection and rework during assembly. This package type is commonly used in microcontrollers, digital signal processors (DSPs), and other integrated circuits where space efficiency and performance are essential. However, the fine pitch of QFP leads can pose challenges during soldering, especially in high-density designs.

Small Outline Integrated Circuit (SOIC)

The Small Outline Integrated Circuit (SOIC) offers a compact and efficient alternative to traditional through-hole packages. Its rectangular body features gull-wing leads on two sides, enabling efficient use of PCB space. SOIC packages typically have a pin spacing of around 1.27mm, which simplifies soldering and assembly processes.

SOIC is highly regarded for its ease of use and versatility. It supports a wide range of applications, including microcontrollers, memory chips, and analog devices. The thin and lightweight design of SOIC packages makes them ideal for modern electronics requiring miniaturization. Additionally, their improved electrical performance and ability to accommodate more pins in a smaller footprint contribute to their popularity in the industry.

"SOIC packaging represents a significant advancement in surface mount technology, offering a thin, compact alternative to traditional through-hole packages."

This package type is particularly suitable for consumer electronics, automotive systems, and industrial equipment where reliability and space optimization are critical.

Small Outline Transistor (SOT)

The Small Outline Transistor (SOT) is a surface-mount equivalent of the conventional through-hole transistor package. SOT packages are compact and designed for applications requiring discrete components like transistors, diodes, and voltage regulators. Their small size and straightforward design make them a preferred choice for high-density PCB layouts.

SOT packages are available in various configurations, such as SOT-23 and SOT-223, catering to different power and performance requirements. These packages are commonly used in power management circuits, RF amplifiers, and switching applications. The simplicity of SOT packaging ensures ease of assembly and compatibility with automated manufacturing processes.

Comparing Ball Grid Array with Other SMT Options

Performance

The Ball grid array (BGA) demonstrates superior performance in high-speed and high-density applications. Its unique design, featuring solder balls arranged in a grid pattern, minimizes electrical resistance and inductance. This results in improved signal integrity and faster data transfer rates. BGA packages also reduce parasitic capacitance, which decreases noise and interference, ensuring reliable operation in demanding environments. These characteristics make BGA an excellent choice for applications requiring high-frequency performance, such as microprocessors and advanced communication systems.

In contrast, other surface mount technologies (SMT), such as Quad Flat Package (QFP) and Small Outline Integrated Circuit (SOIC), may not achieve the same level of electrical efficiency. QFP, with its gull-wing leads, often experiences higher inductance and resistance due to longer connection paths. Similarly, SOIC packages, while compact, may struggle to match the thermal and electrical performance of BGA in high-performance scenarios. For applications where speed and signal clarity are critical, BGA consistently outperforms its counterparts.

Reliability

BGA packages excel in reliability, particularly in environments with high mechanical stress or extreme temperatures. The solder balls in BGA provide robust mechanical support, reducing the risk of damage during operation or handling. Additionally, the compact design enhances thermal conductivity, allowing efficient heat dissipation. This ensures stable performance even under heavy workloads or in harsh conditions, such as those found in industrial or automotive applications.

Other SMT options, like QFP and SOIC, may face challenges in maintaining reliability under similar conditions. The leads in QFP packages are more prone to bending or breaking, especially during assembly or rework. SOIC packages, while durable, may not offer the same level of thermal management as BGA. For applications requiring long-term stability and durability, BGA proves to be a more reliable choice.

Cost

The cost of implementing BGA technology can be higher compared to other SMT options. The manufacturing and testing processes for BGA packages often involve greater complexity, leading to increased production expenses. Additionally, the need for advanced equipment and precise assembly techniques contributes to the overall cost. However, BGA's benefits, such as improved performance and reliability, often justify the investment for high-performance applications.

In comparison, QFP and SOIC packages are generally more cost-effective. Their simpler designs and assembly processes make them suitable for projects with budget constraints. For example, QFP is often used in applications where moderate performance and lower costs are priorities. SOIC, with its straightforward structure, offers an economical solution for compact and lightweight designs. While BGA may not always be the most affordable option, its advantages in high-performance scenarios make it a worthwhile consideration.

Application Suitability

The suitability of Ball Grid Array (BGA) technology depends on the specific requirements of an application. Its unique features make it an excellent choice for high-performance and high-density designs, while other surface mount technologies (SMT) may better serve cost-sensitive or less demanding projects.

When to Choose BGA

BGA packages excel in applications requiring superior electrical performance, efficient thermal management, and compact designs. Their high pin density and grid-like solder ball arrangement allow for faster data transfer and reduced signal interference. These characteristics make BGA ideal for:

High-Performance Computing: Microprocessors, GPUs, and AI processors benefit from BGA's ability to handle high-speed signals and dense interconnections.

Telecommunication Systems: Devices like 5G base stations rely on BGA for its enhanced signal integrity and heat dissipation capabilities.

Consumer Electronics: Smartphones, tablets, and laptops use BGA to achieve sleek designs without sacrificing functionality.

Industrial and Automotive Applications: BGA's mechanical stability and thermal efficiency ensure reliable performance in harsh environments.

"BGA technology offers unmatched performance in scenarios where speed, reliability, and space optimization are critical."

When Other SMT Options Are More Suitable

While BGA provides numerous advantages, other SMT options like Quad Flat Package (QFP), Small Outline Integrated Circuit (SOIC), and Small Outline Transistor (SOT) may be more appropriate for certain applications. These alternatives often involve simpler manufacturing processes and lower costs, making them suitable for:

Cost-Sensitive Projects: QFP and SOIC packages offer economical solutions for applications with moderate performance requirements.

Low-Pin-Count Designs: SOT packages work well for discrete components like transistors and diodes, where high pin density is unnecessary.

Prototyping and Rework-Friendly Designs: QFP's gull-wing leads allow for easier inspection and rework compared to BGA's solder balls.

Balancing Performance and Cost

The decision to use BGA or other SMT options often involves balancing performance needs with budget constraints. For high-performance applications, BGA's benefits in signal integrity, thermal management, and compactness justify its higher manufacturing complexity. However, for simpler designs or cost-sensitive projects, alternatives like QFP or SOIC may provide a more practical solution.

By understanding the strengths and limitations of each technology, designers can select the most suitable option for their specific application, ensuring optimal performance and cost-efficiency.

Advantages and Disadvantages of Ball Grid Array in High-Performance Applications

Advantages

The Ball grid array (BGA) offers several advantages that make it a preferred choice for high-performance applications. Its unique design enhances both electrical and thermal performance, ensuring reliable operation in demanding environments.

Superior Electrical Properties: The short and evenly distributed solder balls in BGA packages reduce inductance and parasitic capacitance. This results in improved signal integrity, reduced noise, and minimized signal interference. These characteristics make BGA ideal for applications requiring high-speed data transmission.

Enhanced Thermal Conductivity: BGA packages excel in dissipating heat efficiently. This capability ensures stable performance even under heavy workloads, making them suitable for devices like microprocessors and GPUs.

Mechanical Stability: The solder balls provide robust mechanical support, allowing BGA packages to withstand high mechanical stress. This feature proves valuable in harsh environments, such as industrial or automotive applications.

Compact Form Factor: The absence of leads and the grid-like arrangement of solder balls enable a smaller footprint. This compact design supports the miniaturization of modern electronic devices, including smartphones and tablets.

High-Density Connections: BGA technology allows for a higher number of connections within a limited space. This makes it suitable for high-density designs, such as advanced communication systems and AI processors.

"BGA technology combines compactness with superior performance, making it indispensable for high-performance systems."

Disadvantages

Despite its numerous advantages, the Ball grid array (BGA) also presents certain challenges that designers must consider when selecting it for high-performance applications.

Complex PCB Design and Assembly: BGA packages require precise PCB design and advanced assembly techniques. The complexity of these processes increases manufacturing costs and demands specialized equipment.

Difficult Inspection and Rework: The solder balls are located beneath the package, making visual inspection challenging. Reworking BGA packages often requires sophisticated tools, which can complicate repairs during prototyping or production.

Higher Cost: The advanced features of BGA packages come with a higher price tag. The increased manufacturing and testing expenses may not align with budget-sensitive projects.

Limited Suitability for Certain Applications: While BGA excels in high-performance scenarios, it may not be the best option for applications prioritizing dependability over size or cost considerations. Simpler SMT options, such as QFP or SOIC, might better serve these needs.

"The benefits of BGA often outweigh its challenges, but careful evaluation is essential to ensure it aligns with specific application requirements."

By understanding both the advantages and disadvantages of BGA, designers can make informed decisions that balance performance, cost, and reliability. This approach ensures optimal outcomes for high-performance applications.

Choosing Ball Grid Array Over Other SMT Options

Scenarios Favoring BGA

Ball Grid Array (BGA) technology proves advantageous in applications demanding high performance, compact designs, and efficient thermal management. Its unique structure, featuring solder balls arranged in a grid pattern, supports high-speed data transmission and superior signal integrity. These characteristics make BGA indispensable in several scenarios:

High-Performance Computing

Devices like microprocessors, GPUs, and AI processors benefit from BGA's ability to handle dense interconnections and high-frequency signals. The shorter electrical paths in BGA packages reduce resistance and inductance, ensuring faster and more reliable performance.Telecommunication Systems

BGA excels in 5G base stations and other advanced communication systems. Its efficient heat dissipation and robust mechanical stability ensure consistent operation under heavy workloads and extreme conditions.Consumer Electronics

Modern devices such as smartphones, tablets, and laptops rely on BGA for their sleek designs and high functionality. The compact form factor of BGA packages allows manufacturers to optimize space without compromising performance.Industrial and Automotive Applications

BGA's resilience to mechanical stress and extreme temperatures makes it ideal for industrial controllers, autonomous vehicles, and other demanding environments. Its robust design ensures long-term reliability in harsh conditions.

"BGA technology continues to evolve, meeting the needs of sectors like artificial intelligence, Industry 4.0, and IoT. Its adaptability ensures its relevance in cutting-edge applications."

In these scenarios, BGA's advantages outweigh its challenges, making it the preferred choice for high-performance systems.

Scenarios Favoring Other SMT Options

While BGA offers numerous benefits, other Surface Mount Technologies (SMT) may better suit specific applications. Simpler designs, lower costs, and easier assembly processes make alternatives like Quad Flat Package (QFP), Small Outline Integrated Circuit (SOIC), and Small Outline Transistor (SOT) more appropriate in certain cases:

Cost-Sensitive Projects

QFP and SOIC packages provide economical solutions for applications with moderate performance requirements. Their straightforward designs reduce manufacturing complexity, making them ideal for budget-conscious projects.Prototyping and Rework-Friendly Designs

QFP's gull-wing leads allow for easier inspection and rework compared to BGA's hidden solder balls. This feature proves valuable during prototyping or when frequent modifications are necessary.Low-Pin-Count Designs

SOT packages work well for discrete components like transistors and diodes. Their small size and simple structure make them suitable for designs where high pin density is unnecessary.Applications with Minimal Thermal Demands

In scenarios where heat dissipation is not a critical factor, SOIC and QFP packages offer sufficient performance without the added complexity of BGA.

"While BGA excels in high-density and high-speed applications, simpler SMT options often provide practical solutions for less demanding projects."

By understanding the strengths of each technology, designers can make informed decisions. Selecting the right SMT option ensures optimal performance, cost-efficiency, and reliability tailored to the specific needs of the application.

Ball grid array technology distinguishes itself from other surface mount options by offering superior performance, reliability, and compactness. Its shorter interconnect lengths and reduced inductance enhance signal integrity and enable high-speed data transfer. BGA packages also excel in thermal management and mechanical stability, making them ideal for high-density and high-performance applications. While alternatives like QFP and SOIC may suit cost-sensitive or simpler designs, BGA remains the optimal choice for complex systems requiring advanced electronic characteristics. Designers should evaluate application needs carefully to select the most suitable technology for their projects.

See Also

Zhongkai's Breakthrough In High-Energy Battery Technology

Discovering Zhongkai: Unexpected Advantages for Mobile Manufacturing

Transforming Semiconductor Displays: Zhongkai's Major Investment and Expansion

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271