Emerging Trends in Ball Grid Array Technology

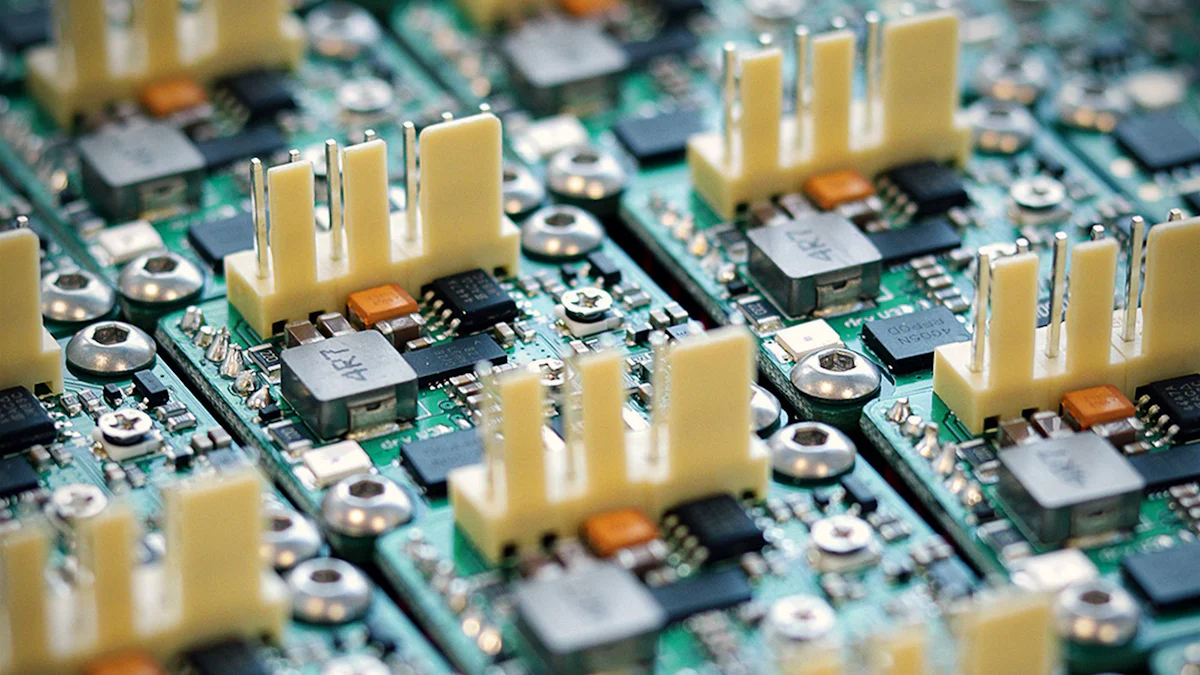

Ball grid array technology has revolutionized modern electronics by offering a compact and efficient solution for semiconductor packaging. It enables higher density interconnections, which are essential for the miniaturization of devices. This technology plays a critical role in improving thermal performance and ensuring reliable high-speed operations. Industries such as automotive, aerospace, and consumer electronics increasingly rely on ball grid arrays to meet the growing demand for high-performance and energy-efficient devices. As urbanization and industrial development accelerate, especially in emerging economies, the adoption of this advanced packaging solution continues to expand.

Key Takeaways

Ball grid array (BGA) technology is essential for miniaturizing electronic devices, enabling higher integration without sacrificing performance.

Advanced thermal management in BGA packages enhances device reliability and lifespan by efficiently dissipating heat, crucial for high-performance applications.

Increasing pin counts in BGA designs facilitate efficient signal transmission, making them ideal for data-intensive fields like 5G and IoT.

BGA technology supports the growing demand for compact and reliable components in automotive electronics, particularly for advanced driver-assistance systems.

The adoption of BGA technology in telecommunications is driven by the need for precise signal integrity and thermal management in 5G infrastructure.

Manufacturers are addressing reliability challenges in BGA technology through advanced materials and rigorous testing to ensure durability in extreme conditions.

Automated assembly and advanced inspection technologies are key to overcoming manufacturing complexities, ensuring high-quality BGA components.

Latest Advancements in Ball Grid Array Technology

Miniaturization and Compact Designs

The demand for smaller, more efficient electronic devices has driven significant advancements in ball grid array technology. Manufacturers now prioritize miniaturization to meet the needs of industries like wearables, IoT devices, and mobile electronics. By reducing the size of components, BGA packaging enables higher integration levels without compromising performance. This innovation supports the development of compact devices with enhanced functionality.

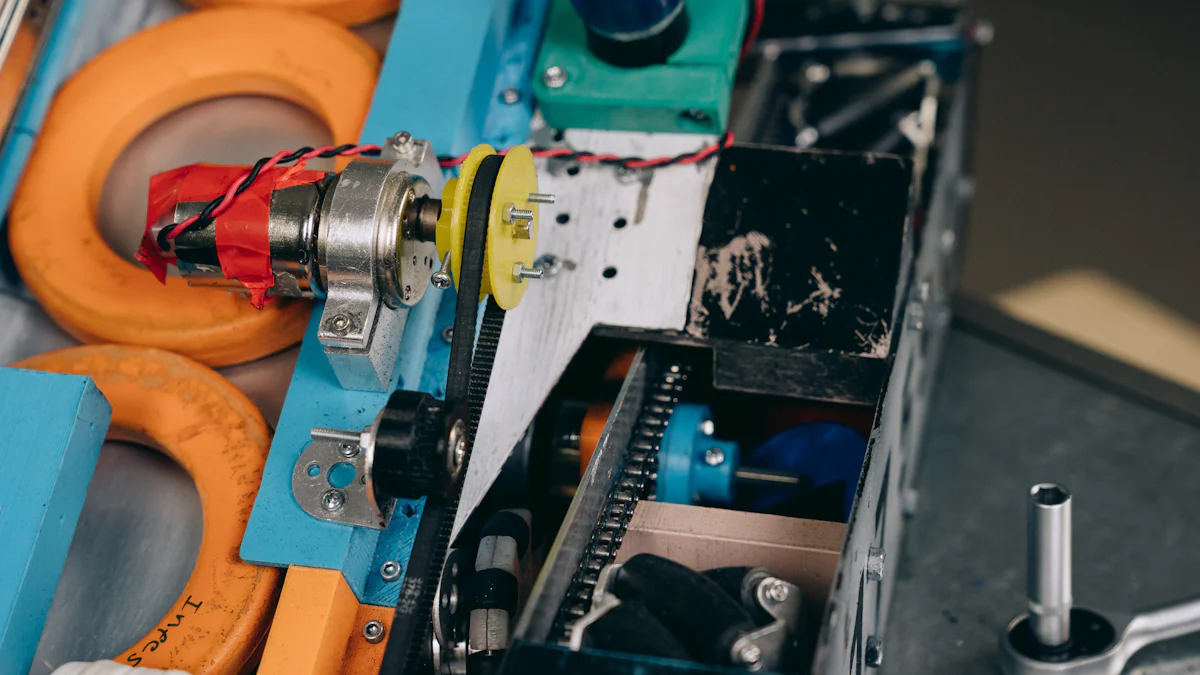

Modern BGA designs utilize advanced materials and manufacturing techniques to achieve these goals. For instance, reflow soldering and automated assembly equipment ensure precision during production. These methods improve the quality and reliability of BGA packages, making them ideal for high-performance applications. Additionally, the compact nature of BGA technology allows for better utilization of printed circuit board (PCB) space, which enhances overall device efficiency.

Improved Thermal Management

As electronic devices become more powerful, managing heat effectively has become a critical challenge. Ball grid array technology addresses this issue by incorporating materials with superior thermal conductivity. These materials dissipate heat efficiently, ensuring optimal performance even under high power densities. Enhanced thermal control not only improves device reliability but also extends the lifespan of electronic components.

Innovations in thermal management have made BGA packages indispensable in industries like automotive and telecommunications. For example, advanced packaging solutions now integrate heat spreaders and thermal vias to handle increased power demands. These features allow devices to operate at higher speeds without overheating, which is essential for applications requiring consistent performance.

Higher Pin Counts and Signal Integrity

The evolution of ball grid array technology has also focused on increasing pin counts to support complex electronic systems. Higher pin counts enable more connections between the chip and the PCB, facilitating efficient signal transmission. This advancement is crucial for modern devices that require high-speed data processing and communication.

Maintaining signal integrity is another priority in BGA design. Engineers employ innovative techniques to minimize signal loss and interference, ensuring reliable performance. For instance, optimized PCB layouts and advanced inspection technologies enhance the dependability of BGA packages. These improvements make BGA technology a preferred choice for applications in 5G networks, IoT, and other data-intensive fields.

Emerging Applications of Ball Grid Array Technology

Internet of Things (IoT)

The Internet of Things (IoT) has transformed how devices interact and share data. Ball grid array technology plays a pivotal role in this transformation by enabling compact and efficient designs for IoT devices. These devices, such as smart home systems, wearable health monitors, and industrial sensors, demand high-performance components in small form factors. BGA packaging meets these requirements by offering higher pin counts and superior thermal management.

Manufacturers rely on BGA technology to enhance the reliability and functionality of IoT devices. For instance, its efficient use of space allows for the integration of multiple features into a single device. Additionally, the electrical properties of BGA packages ensure stable and high-speed data transmission, which is critical for IoT applications. As IoT adoption grows, the demand for advanced BGA solutions continues to rise.

Automotive Electronics

The automotive industry increasingly depends on ball grid array technology to meet the demands of modern vehicles. Advanced driver-assistance systems (ADAS), infotainment systems, and engine control units require compact and reliable electronic components. BGA packaging provides the necessary performance and durability for these applications.

Automotive electronics benefit from the thermal dissipation capabilities of BGA packages. These capabilities ensure that components operate efficiently under extreme conditions. Furthermore, the high pin count of BGA technology supports the complex circuitry found in modern vehicles. This makes it an ideal choice for power modules and other critical systems. As the automotive sector embraces electric and autonomous vehicles, the role of BGA technology becomes even more significant.

5G and Telecommunications

The rollout of 5G networks has accelerated the adoption of ball grid array technology in telecommunications. BGA packages are essential for advanced RF components and high-frequency modules used in 5G infrastructure. These components require precise signal integrity and efficient thermal management, both of which are strengths of BGA technology.

Telecommunications equipment, such as base stations and network routers, relies on BGA packaging to handle high-speed data processing. The compact design of BGA packages also supports the miniaturization of devices, which is crucial for modern communication systems. As 5G technology expands globally, the demand for innovative BGA solutions will continue to grow.

Challenges and Solutions in Ball Grid Array Technology

Reliability and Durability

Reliability and durability remain critical concerns in ball grid array technology. Electronic devices often operate in environments that expose components to extreme temperatures, mechanical stress, and prolonged usage. These conditions can lead to solder joint fatigue, cracking, or delamination, which compromise the performance of BGA packages. Manufacturers address these challenges by employing advanced materials and innovative design techniques.

For instance, the use of lead-free solder alloys enhances the mechanical strength of solder joints, reducing the risk of failure under thermal cycling. Additionally, encapsulation methods protect BGA packages from environmental factors such as moisture and contaminants. Engineers also conduct rigorous testing, including thermal shock and vibration tests, to ensure the reliability of BGA components in demanding applications.

To further improve durability, manufacturers integrate features like underfill materials. These materials distribute mechanical stress evenly across the package, minimizing the likelihood of solder joint damage. Such advancements make ball grid array technology a dependable choice for industries requiring high-performance and long-lasting electronic solutions.

Manufacturing Complexities

The manufacturing process for ball grid array technology presents unique challenges due to its intricate design and high precision requirements. The compact size and high pin density of BGA packages demand meticulous attention during assembly and inspection. Errors such as misalignment or insufficient soldering can lead to functional defects, impacting the overall quality of the product.

To overcome these complexities, manufacturers leverage automated assembly equipment and advanced inspection technologies. Automated systems, such as pick-and-place machines, ensure accurate placement of BGA components on printed circuit boards (PCBs). Reflow soldering techniques provide consistent and reliable solder connections, reducing the risk of defects.

Inspection processes play a vital role in maintaining quality standards. X-ray imaging and automated optical inspection (AOI) systems detect hidden defects, such as voids or misaligned solder balls, that are not visible to the naked eye. These technologies enable manufacturers to identify and rectify issues early in the production cycle, ensuring the reliability of the final product.

Despite these advancements, the cost of implementing such sophisticated manufacturing processes remains a concern. However, the benefits of improved performance, higher pin density, and enhanced thermal management outweigh the challenges, making BGA technology an essential component in modern electronics.

Ball grid array technology continues to redefine the electronics industry by driving advancements in miniaturization, thermal management, and signal integrity. Its applications in IoT, automotive electronics, and 5G telecommunications highlight its versatility and growing importance. These trends not only address current challenges but also pave the way for future innovations. By embracing cutting-edge solutions, manufacturers can enhance device performance and reliability. The ongoing evolution of BGA technology underscores its critical role in shaping the future of electronics, ensuring that it meets the demands of increasingly complex and compact devices.

See Also

Transforming Semiconductor Displays: Zhongkai's Billion-Dollar Investment Initiative

Innovative Advances in Huizhou Zhongkai High-Tech Zone

Zhongkai's Game-Changing High-Power Battery Innovations

Zhongkai High-Tech Zone: Center for Smart Device Advancements

Mobile Smart Terminal Production Base: Easily Reach EVE Energy

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271