Industrial Automation Robotics Compared

Industrial automation has entered a transformative era, with robotics playing a pivotal role in reshaping production processes. The global robotics market, valued at $46 billion in 2023, is projected to grow at a compound annual growth rate of 15.1%, reaching $169.8 billion by 2032. This rapid expansion highlights the increasing demand for efficient, cost-effective solutions. Selecting the right robotics system is crucial, as it directly impacts operational efficiency, safety, and return on investment. The key question remains: how do various robotics solutions compare in terms of features, costs, and applications?

Key Takeaways

Robotics is transforming industries by automating repetitive tasks, enhancing productivity, and ensuring consistent quality.

Collaborative robots (cobots) offer flexibility and safety, making them ideal for environments where human interaction is essential.

Investing in robotics can lead to significant cost savings by reducing labor expenses and minimizing waste over time.

Understanding the specific needs of your operations is crucial for selecting the right robotics solution, whether it's for precision, speed, or adaptability.

Scalable robotics solutions allow businesses to grow without major reinvestments, ensuring they remain competitive in dynamic markets.

Integrating AI and IoT with robotics enhances operational efficiency and supports predictive maintenance, driving innovation in industrial automation.

Prioritizing sustainability in robotics not only reduces environmental impact but also leads to long-term cost savings and improved brand reputation.

Overview of Robotics in Industrial Automation

The Role of Robotics in Transforming Industries

Robotics has become a cornerstone of industrial transformation, driving efficiency and innovation across multiple sectors. By automating repetitive and labor-intensive tasks, robotics enables industries to achieve higher productivity levels while maintaining consistent quality. For instance, in manufacturing, robots streamline assembly lines, reducing production time and minimizing human error. This shift not only enhances operational efficiency but also allows companies to meet growing consumer demands with precision.

The electric vehicle (EV) industry exemplifies the transformative power of robotics. Robots play a critical role in battery production, ensuring sustainability and improving manufacturing speed. According to Schneider Electric, robotics has significantly optimized the production process for EV batteries, contributing to the industry's rapid growth. Similarly, logistics and warehousing operations have embraced robotics to improve inventory management and order fulfillment, resulting in faster delivery times and reduced costs.

Governments worldwide recognize the importance of robotics in industrial transformation. Many provide grants, tax incentives, and research funding to encourage innovation and competitiveness. This support has accelerated the adoption of robotics, making it a vital component of modern industrial strategies.

Key Benefits of Robotics in Automation

The integration of robotics into industrial automation offers numerous advantages that extend beyond productivity. One of the most significant benefits is cost reduction. By automating tasks, companies can lower labor costs and reduce waste, leading to substantial long-term savings. Additionally, robotics enhances workplace safety by taking over hazardous tasks, minimizing the risk of workplace injuries.

Robotics also improves product quality by ensuring precision and consistency in manufacturing processes. For example, in the food and beverage industry, robots handle delicate tasks like packaging and sorting with unmatched accuracy. This level of precision reduces errors and enhances customer satisfaction.

Flexibility is another key advantage. Collaborative robots, or cobots, are designed to work alongside human employees, adapting to various tasks with ease. Their user-friendly programming makes them ideal for smaller operations or industries requiring frequent task changes. As noted by Enterprise Apps Today, robotics is increasingly utilized in diverse fields such as healthcare and domestic tasks, showcasing its versatility.

Finally, robotics contributes to sustainability efforts. By optimizing resource usage and reducing waste, robotics supports environmentally friendly practices. This aligns with global initiatives to create more sustainable industrial processes, further solidifying its role in shaping the future of automation.

Key Types of Robotics Solutions

Collaborative Robots (Cobots)

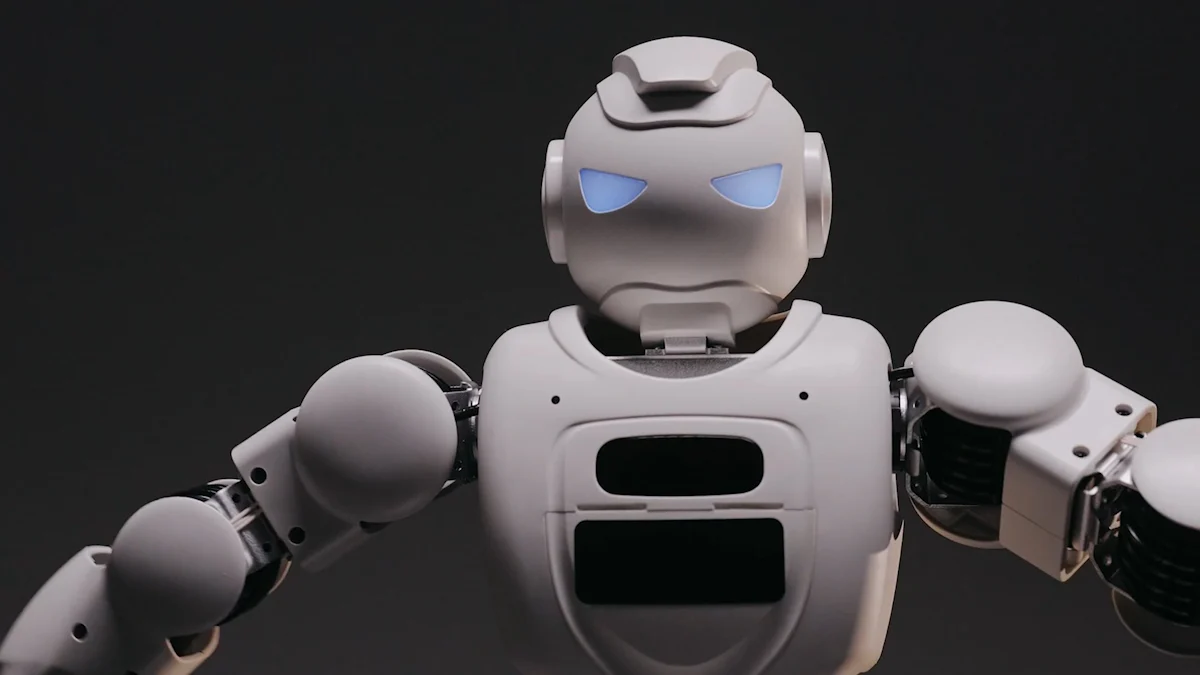

Collaborative robots, commonly referred to as cobots, represent a groundbreaking advancement in industrial automation. Unlike traditional robots, cobots are designed to work directly alongside human workers without the need for physical barriers such as safety fences. This unique capability stems from their advanced safety features, which include sensors and force-limiting technology that prevent harm during human-robot interaction. These features make cobots ideal for environments where space is limited or where human oversight is essential.

Cobots excel in tasks requiring precision and adaptability. Their lightweight design and user-friendly programming allow businesses to deploy them quickly for various applications, such as assembly, packaging, and quality inspection. For smaller operations or industries with frequent task changes, cobots provide a cost-effective and flexible solution. However, their reliance on human interaction for programming and maintenance can limit their operational speed compared to traditional robots. Despite this, cobots have made automation accessible to many organizations that previously found traditional robotics solutions out of reach.

"Cobots have revolutionized automation by enabling safe and efficient collaboration between humans and machines," as highlighted by industry experts. Their growing popularity underscores their role in shaping the future of industrial automation.

Industrial Robots

Industrial robots serve as the backbone of large-scale automation. These robots operate independently once programmed, requiring minimal human intervention during daily operations. Their robust design and high-speed capabilities make them suitable for repetitive, heavy-duty tasks such as welding, painting, and assembly. Industries like automotive manufacturing and electronics rely heavily on industrial robots to achieve precision and consistency in production.

The integration of industrial robots with advanced technologies such as artificial intelligence (AI) and cloud computing has further expanded their capabilities. For example, AI-powered robots can perform quality control by identifying defects with unparalleled accuracy. In logistics, industrial robots streamline warehousing operations by automating sorting and transportation tasks. Their ability to handle complex processes with efficiency makes them indispensable in sectors demanding high productivity and reduced operational costs.

Industrial robots, however, often require significant upfront investment and dedicated space for operation. Despite these challenges, their long-term benefits in terms of efficiency and scalability make them a preferred choice for large enterprises.

Mobile Robots and AGVs (Automated Guided Vehicles)

Mobile robots and AGVs represent a dynamic category of robotics solutions designed for mobility and versatility. These robots navigate industrial environments autonomously, using sensors and mapping technologies to perform tasks such as material handling, inventory management, and order fulfillment. Their ability to move freely across factory floors or warehouses eliminates the need for fixed conveyor systems, offering greater flexibility in operations.

AGVs follow predefined paths, making them ideal for structured environments with repetitive workflows. In contrast, mobile robots equipped with advanced navigation systems can adapt to changing layouts and avoid obstacles in real time. This adaptability makes them suitable for industries like logistics, where operational demands frequently shift.

The adoption of mobile robots and AGVs has surged due to their ability to enhance productivity while reducing labor costs. By automating transportation tasks, these robots free up human workers to focus on more complex responsibilities. Their role in optimizing supply chain operations highlights their importance in modern industrial strategies.

Detailed Feature Comparison

Safety Features

Safety remains a critical consideration in industrial automation. Collaborative robots (cobots) prioritize safety through advanced features like force-limiting sensors and real-time monitoring systems. These technologies enable cobots to detect human presence and adjust their movements to prevent accidents. This makes them ideal for environments where humans and robots work closely together.

In contrast, traditional industrial robots often require physical barriers, such as safety fences, to ensure worker protection. Their high-speed operations and heavy payload capacities necessitate these precautions. However, advancements in robotics have introduced safety upgrades, including emergency stop functions and collision detection systems, even in traditional robots. These features enhance operational safety while maintaining efficiency.

"Safety is not just a feature; it is a necessity in modern industrial robotics," as emphasized by industry leaders. Companies must evaluate the safety requirements of their operations when selecting a robotics solution.

Flexibility and Adaptability

Flexibility defines the usability of robotics in dynamic industrial settings. Cobots excel in this area due to their lightweight design and intuitive programming interfaces. Businesses can quickly reprogram cobots for various tasks, such as assembly, inspection, or packaging. This adaptability makes cobots suitable for industries with frequent task changes or smaller-scale operations.

Traditional industrial robots, while less flexible, offer unparalleled precision and efficiency in repetitive tasks. Their rigid programming and specialized designs make them ideal for large-scale production lines. For example, Cartesian robots perform linear movements with high accuracy, while articulated robots handle complex, multi-axis tasks. Each type of industrial robot caters to specific operational needs, ensuring optimal performance in its designated role.

The choice between cobots and traditional robots depends on the operational demands. Cobots provide versatility, while traditional robots deliver consistency in high-volume production.

Speed and Precision

Speed and precision are essential for achieving operational efficiency. Traditional industrial robots dominate in this aspect, offering rapid cycle times and exceptional accuracy. Their ability to perform repetitive tasks without fatigue ensures consistent output. For instance, delta robots excel in high-speed pick-and-place operations, making them indispensable in industries like electronics and food processing.

Cobots, while slower than traditional robots, compensate with their precision and collaborative capabilities. Their speed aligns with human operators, ensuring seamless integration into workflows. This balance of speed and precision makes cobots valuable for tasks requiring human oversight or intricate handling.

Mobile robots and AGVs also contribute to operational efficiency by automating material transport. Their navigation systems ensure precise movement, reducing delays and errors in logistics. These robots enhance productivity by streamlining processes across various sectors.

Cost and Maintenance

Cost and maintenance play a pivotal role in determining the feasibility of robotics solutions for industrial automation. Businesses must evaluate both upfront expenses and long-term operational costs to make informed decisions.

1. Initial Investment

Industrial robots typically require a higher initial investment compared to collaborative robots (cobots). The price range for industrial robots falls between $50,000 and $150,000, depending on their type and capabilities. These robots often demand additional expenditures for installation, programming, and safety infrastructure, such as barriers or enclosures. In contrast, cobots offer a more cost-effective alternative. Their simplified programming and built-in safety features reduce setup costs, making them accessible to smaller operations or businesses with limited budgets.

2. Maintenance Costs

Maintenance expenses vary significantly between industrial robots and cobots. Industrial robots, designed for heavy-duty tasks, require regular servicing to ensure optimal performance. Their complex components, such as actuators and sensors, necessitate specialized technicians for repairs and upkeep. Cobots, on the other hand, feature simpler designs and user-friendly interfaces, which minimize maintenance requirements. Businesses can often handle basic troubleshooting and updates in-house, further reducing costs.

3. Operational Efficiency and Longevity

While industrial robots demand higher upfront and maintenance costs, their durability and efficiency often justify the investment. These robots excel in repetitive, high-speed tasks, ensuring consistent output over extended periods. Cobots, although less robust, provide flexibility and adaptability, which can lead to cost savings in dynamic environments. Their ability to collaborate with human workers enhances productivity without requiring extensive modifications to existing workflows.

4. Hidden Costs to Consider

Beyond direct expenses, businesses should account for hidden costs associated with robotics adoption. For industrial robots, these may include training employees to operate and maintain the systems, as well as potential downtime during installation or upgrades. Cobots, while easier to integrate, may incur costs related to software updates or compatibility with existing equipment. Evaluating these factors ensures a comprehensive understanding of the total cost of ownership.

"Investing in robotics is not just about the purchase price; it’s about understanding the long-term value it brings to operations," as emphasized by industry experts. Companies must weigh the benefits of efficiency and scalability against the financial commitment required.

By carefully analyzing cost and maintenance factors, businesses can select the robotics solution that aligns with their operational goals and budget constraints.

Industry-Specific Applications and Use Cases

Automotive Industry

The automotive industry has embraced robotics to revolutionize production processes. Industrial robots dominate assembly lines, performing tasks such as welding, painting, and component installation with unmatched precision. These robots ensure consistent quality, reduce production lead times, and minimize waste. By automating repetitive tasks, manufacturers achieve higher productivity while lowering operational costs. For instance, robotic systems can reduce total manufacturing costs by 20% to 60%, making them indispensable for large-scale operations.

Collaborative robots (cobots) also play a significant role in automotive manufacturing. Cobots assist human workers in tasks requiring dexterity, such as assembling intricate components or inspecting finished products. Their ability to work safely alongside humans enhances flexibility on the production floor. This collaboration improves efficiency without compromising safety standards. The integration of cobots into automotive factories demonstrates how robotics adapts to evolving industry needs.

"Robotics has transformed the automotive sector by streamlining production and ensuring consistent quality," as noted by industry leaders. This transformation highlights the importance of robotics in maintaining competitiveness in a fast-paced market.

Electronics Manufacturing

Electronics manufacturing demands precision and speed, making robotics an ideal solution. Industrial robots excel in assembling delicate components, such as circuit boards and microchips, with extreme accuracy. Their high-speed operations ensure consistent output, reducing the risk of defects. By automating these processes, manufacturers achieve higher yields and lower production costs.

Cobots have gained popularity in electronics manufacturing due to their adaptability. These robots handle tasks like soldering, testing, and packaging with ease. Their user-friendly programming allows businesses to reconfigure them for different applications, making them suitable for dynamic production environments. Cobots also enhance workplace safety by taking over tasks involving hazardous materials or repetitive motions.

Mobile robots and AGVs further optimize electronics manufacturing by streamlining material handling. These robots transport components across factory floors, ensuring timely delivery to assembly stations. Their ability to navigate complex layouts enhances operational efficiency, reducing downtime and improving overall productivity.

Food and Beverage Industry

The food and beverage industry relies on robotics to meet stringent hygiene standards and maintain product quality. Industrial robots perform tasks such as sorting, packaging, and palletizing with precision and consistency. These robots reduce human contact with food products, minimizing contamination risks and ensuring compliance with safety regulations.

Cobots bring flexibility to food processing operations. They handle delicate tasks, such as decorating cakes or assembling meal kits, with care and accuracy. Their compact design makes them suitable for small-scale facilities with limited space. Cobots also adapt to seasonal demand fluctuations, providing cost-effective solutions for businesses with varying production needs.

Mobile robots and AGVs enhance logistics within the food and beverage sector. These robots automate inventory management and order fulfillment, ensuring timely delivery of products to retailers. Their ability to operate in cold storage environments further expands their applications, making them valuable assets in this industry.

"The adoption of robotics in the food and beverage industry ensures efficiency, safety, and quality," as highlighted by experts. This integration supports businesses in meeting consumer expectations while maintaining profitability.

Logistics and Warehousing

Logistics and warehousing operations have undergone a significant transformation with the integration of robotics. These technologies streamline processes, enhance efficiency, and reduce operational costs. Businesses increasingly rely on robotic solutions to meet the growing demands of e-commerce and global supply chains.

1. Material Handling and Inventory Management

Robots excel in material handling tasks, such as picking, sorting, and transporting goods. Automated Guided Vehicles (AGVs) and mobile robots navigate warehouses autonomously, ensuring precise movement of inventory. Their advanced sensors and mapping technologies allow them to avoid obstacles and adapt to dynamic environments. This capability eliminates the need for fixed conveyor systems, offering greater flexibility in warehouse layouts.

Inventory management also benefits from robotics. Robots equipped with scanning and tracking systems perform real-time inventory checks, reducing errors and improving accuracy. By automating these tasks, businesses minimize manual labor and ensure timely stock replenishment.

2. Order Fulfillment and Packaging

Robotics enhances order fulfillment by accelerating the picking and packing process. High-speed robotic arms handle repetitive tasks with precision, ensuring consistent quality. For example, in e-commerce warehouses, robots sort and package items efficiently, meeting tight delivery deadlines. This automation reduces lead times and improves customer satisfaction.

Collaborative robots (cobots) play a vital role in packaging operations. Their user-friendly programming allows businesses to deploy them quickly for various tasks, such as labeling or assembling custom orders. Cobots work alongside human employees, enhancing productivity without compromising safety.

3. Cost Reduction and ROI

The adoption of robotics in logistics and warehousing leads to significant cost savings. By automating labor-intensive tasks, businesses reduce workforce expenses and minimize errors that result in costly rework. Industrial robots, with their high uptime and consistent performance, deliver long-term value. Although the initial investment may be substantial, the return on investment (ROI) justifies the expenditure over time.

Cobots offer a more affordable alternative for smaller operations. Their lower setup costs and quicker ROI make them accessible to businesses with limited budgets. This affordability, combined with their adaptability, positions cobots as a practical solution for dynamic warehousing needs.

"Investing in robotics enhances productivity while reducing risks associated with manual labor," as noted by industry experts. This shift underscores the importance of robotics in modern logistics strategies.

4. Workplace Safety and Efficiency

Robotics improves workplace safety by taking over hazardous tasks, such as lifting heavy loads or operating in extreme conditions. Mobile robots and AGVs reduce the risk of workplace injuries by automating transportation tasks. Their ability to operate continuously without fatigue ensures consistent output, further enhancing efficiency.

The integration of robotics into logistics and warehousing operations aligns with global trends toward automation. By leveraging these technologies, businesses optimize supply chain performance, reduce costs, and maintain a competitive edge in the market.

Cost Analysis and ROI Considerations

Upfront Costs vs. Long-Term Savings

The initial investment in robotics solutions often represents a significant financial commitment. Industrial robots, known for their high-speed capabilities and precision, typically require upfront costs ranging from $50,000 to $150,000. These expenses include not only the robot itself but also installation, programming, and safety infrastructure. For example, in the automotive industry, robots performing tasks like welding and painting demand robust systems, which contribute to these higher costs.

Collaborative robots (cobots), on the other hand, offer a more affordable entry point. Their simplified design and built-in safety features reduce installation and programming expenses. Businesses with smaller budgets or operations requiring frequent task changes often find cobots to be a cost-effective alternative. In the food and beverage industry, cobots handle packaging and sorting tasks efficiently, demonstrating their value in environments with limited resources.

While the upfront costs may seem daunting, the long-term savings often outweigh the initial expenditure. Robotics solutions reduce labor costs, minimize errors, and enhance productivity. Over time, these benefits translate into substantial financial gains, making the investment worthwhile for many industries.

Calculating ROI for Robotics Investments

Return on investment (ROI) serves as a critical metric for evaluating the financial viability of robotics adoption. Businesses must consider several factors when calculating ROI, including productivity gains, labor cost reductions, and operational efficiency improvements. For instance, in logistics and warehousing, robots streamline material handling and inventory management, leading to faster order fulfillment and reduced operational costs.

To calculate ROI, companies can use the following formula:

ROI (%) = [(Net Benefits - Initial Investment) / Initial Investment] × 100

Net benefits include cost savings from reduced labor, increased output, and minimized errors. For example, in electronics manufacturing, robots assembling delicate components with precision reduce defect rates, resulting in higher yields and lower production costs. By quantifying these benefits, businesses can determine the payback period and long-term profitability of their robotics investments.

Hidden Costs to Consider

Beyond the visible expenses, hidden costs often influence the total cost of ownership for robotics solutions. Training employees to operate and maintain robots represents one such cost. Industrial robots, with their complex systems, require specialized technicians for repairs and updates. This need for expertise can increase maintenance expenses over time.

Downtime during installation or upgrades also impacts operational efficiency. Businesses must plan for potential disruptions when integrating robotics into existing workflows. In contrast, cobots, with their user-friendly interfaces, minimize downtime and training requirements, offering a smoother transition.

Compatibility with existing equipment and software presents another hidden cost. Companies may need to invest in additional infrastructure or software updates to ensure seamless integration. For example, mobile robots in logistics require advanced navigation systems to adapt to dynamic environments, which may necessitate further technological investments.

"Understanding the hidden costs of robotics adoption ensures a comprehensive evaluation of its financial impact," as emphasized by industry experts. Businesses must account for these factors to make informed decisions and maximize the value of their investments.

By addressing both visible and hidden costs, companies can develop a holistic understanding of the financial implications of robotics adoption. This approach enables them to select solutions that align with their operational goals and budget constraints.

Decision-Making Factors

Task Type and Complexity

The type and complexity of tasks play a pivotal role in selecting the right robotics solution. Industries must evaluate whether the tasks require precision, speed, or adaptability. For repetitive and high-speed operations, such as welding or painting in automotive manufacturing, industrial robots excel due to their robust design and efficiency. These robots ensure consistent output and reduce human error, making them indispensable for large-scale production.

In contrast, tasks involving intricate handling or frequent changes benefit from collaborative robots (cobots). Cobots adapt quickly to new tasks, making them ideal for industries like electronics manufacturing, where assembly processes often vary. Their ability to work alongside humans enhances flexibility without compromising safety. For example, Nature Fresh Farms implemented automated solutions for harvesting tomatoes, showcasing how robotics can handle delicate tasks with precision.

Mobile robots and AGVs (Automated Guided Vehicles) address tasks requiring mobility and navigation. These robots streamline material handling and inventory management in logistics and warehousing. By automating transportation tasks, they improve operational efficiency and free up human workers for more complex responsibilities. Businesses must assess the specific requirements of their operations to determine the most suitable robotics solution.

Key takeaway: Matching the robotics solution to the task type ensures optimal performance and maximizes productivity.

Work Environment and Space Constraints

The work environment significantly influences the choice of robotics. Factories with limited space often benefit from cobots due to their compact design and ability to operate without safety barriers. Cobots integrate seamlessly into existing workflows, making them suitable for small-scale facilities or industries with spatial limitations. Their lightweight structure also allows for easy relocation, enhancing operational flexibility.

Industrial robots, while highly efficient, require dedicated space for installation and operation. These robots often necessitate safety enclosures to protect workers, which can limit their use in confined environments. However, their high-speed capabilities make them ideal for large-scale production lines where space is not a constraint.

Warehouses and logistics centers, such as those in the Huizhou Zhongkai High-tech Zone, leverage mobile robots to optimize inventory management and streamline order fulfillment. Their ability to operate in diverse settings makes them a versatile choice for industries with evolving spatial needs.

"Robotics solutions must align with the physical constraints of the workspace to ensure seamless integration," as emphasized by industry experts.

Workforce Skills and Training Requirements

The skill level of the workforce determines the ease of robotics adoption. Cobots, known for their user-friendly programming, require minimal training. Employees can quickly learn to operate and reprogram these robots, reducing downtime during implementation. This accessibility makes cobots an attractive option for businesses with limited technical expertise.

Industrial robots, on the other hand, demand specialized knowledge for programming and maintenance. Companies must invest in training programs to equip their workforce with the necessary skills. While this may increase initial costs, the long-term benefits of enhanced productivity and reduced errors often justify the investment. For instance, in manufacturing, robotics has proven to lower operational costs by up to 30%, highlighting the value of skilled operators.

Mobile robots and AGVs also require training, particularly in navigation and system integration. Employees must understand how to manage these robots to ensure smooth operations. Businesses should consider the availability of skilled technicians and the complexity of the robotics system when making decisions.

Pro Tip: Investing in workforce training enhances the efficiency and longevity of robotics solutions, ensuring a higher return on investment.

Scalability and Future Needs

Scalability plays a crucial role in determining the long-term value of robotics solutions. Businesses must evaluate whether their chosen systems can adapt to evolving operational demands and industry trends. Robotics solutions that support scalability allow companies to expand their capabilities without requiring significant reinvestment.

Industries experiencing rapid growth, such as electric vehicle (EV) manufacturing, highlight the importance of scalable robotics. The EV market demands high-precision battery production, a task robotics excels at handling. As production volumes increase, scalable robotic systems ensure manufacturers can meet demand without compromising quality or efficiency. This adaptability positions robotics as a cornerstone for industries with fluctuating or expanding needs.

"Scalable robotics solutions empower businesses to grow without disruption, ensuring they remain competitive in dynamic markets," according to industry experts.

Key Considerations for Scalability

Modular Design Robotics systems with modular designs offer flexibility for future upgrades. Businesses can add components or enhance functionalities as operational requirements evolve. For example, mobile robots in logistics can integrate advanced navigation systems to handle more complex warehouse layouts. This modularity reduces the need for complete system overhauls, saving time and costs.

Integration with Emerging Technologies The ability to integrate with technologies like artificial intelligence (AI), machine learning, and the Internet of Things (IoT) ensures robotics solutions remain relevant. AI-powered robots enhance decision-making and precision, while IoT connectivity enables real-time monitoring and data analysis. In logistics, these integrations streamline inventory management and improve supply chain efficiency.

Adaptability to Industry Trends Robotics solutions must align with industry-specific advancements. For instance, the rise of automation in agriculture demonstrates how robotics adapts to new applications. Nature Fresh Farms implemented automated systems for harvesting tomatoes, showcasing how robotics evolves to meet unique challenges. This adaptability ensures businesses can leverage robotics across diverse sectors.

Support for Workforce Evolution Scalable robotics solutions consider workforce dynamics. As automation reshapes job roles, businesses must ensure their systems complement human skills. Collaborative robots (cobots) exemplify this approach by working alongside employees, enhancing productivity without replacing human expertise. This balance supports workforce development while meeting operational goals.

Planning for Future Needs

Businesses must anticipate future requirements when selecting robotics solutions. Factors such as market growth, technological advancements, and sustainability goals influence these decisions. For example, the Huizhou Zhongkai High-tech Zone leverages robotics to optimize logistics and warehousing operations, preparing for increased demand in global supply chains. This forward-thinking approach ensures long-term success.

Pro Tip: Investing in scalable robotics solutions minimizes risks associated with obsolescence, ensuring businesses remain agile in competitive markets.

By prioritizing scalability and aligning robotics investments with future needs, companies can achieve sustainable growth. This strategic focus positions robotics as a vital asset in navigating the complexities of modern industrial landscapes.

Future Trends in Industrial Robotics

Advancements in AI and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are revolutionizing the robotics industry. These technologies enable robots to process vast amounts of data, learn from their environments, and make decisions with minimal human intervention. AI-powered robots can now perform complex tasks such as quality control, predictive maintenance, and real-time problem-solving. For example, in manufacturing, robots equipped with AI can identify defects in products with unparalleled accuracy, reducing waste and improving overall efficiency.

Machine learning enhances the adaptability of robots. By analyzing historical data, robots can optimize their performance over time. This capability proves invaluable in industries like logistics, where operational demands frequently change. Robots can adjust to new layouts, improve navigation, and streamline workflows without requiring extensive reprogramming. According to industry reports, global spending on robotics and related services reached $98.4 billion in 2023, reflecting a 27% increase from the previous year. This growth underscores the increasing reliance on AI and ML to drive innovation in robotics.

"AI and machine learning are not just tools; they are the future of robotics," as noted by experts. These advancements ensure that robots remain at the forefront of industrial transformation.

Increased Adoption of Cobots

Collaborative robots, or cobots, are gaining traction across industries due to their versatility and ease of use. Unlike traditional robots, cobots work alongside human employees, enhancing productivity without replacing the workforce. Their user-friendly programming and built-in safety features make them accessible to businesses of all sizes. Cobots excel in tasks requiring precision and adaptability, such as assembly, packaging, and inspection.

The adoption of cobots is expected to rise significantly in the coming years. Around 90% of businesses worldwide plan to implement robotic automation by 2030. This trend highlights the growing recognition of cobots as a cost-effective solution for dynamic operations. In sectors like electronics manufacturing, cobots handle delicate components with care, ensuring consistent quality. Their ability to adapt to various tasks makes them indispensable in industries with frequent production changes.

Cobots also contribute to workplace safety. By taking over hazardous or repetitive tasks, they reduce the risk of injuries and improve overall working conditions. This focus on safety aligns with global efforts to create more sustainable and human-centric industrial environments.

"Cobots represent the perfect blend of human ingenuity and robotic precision," as emphasized by industry leaders. Their increasing adoption reflects a shift toward more collaborative and flexible automation solutions.

Integration with IoT and Smart Factories

The Internet of Things (IoT) is transforming industrial robotics by enabling seamless connectivity between machines, systems, and processes. IoT-integrated robots can communicate with other devices in real time, facilitating data exchange and improving operational efficiency. In smart factories, this connectivity allows robots to monitor production lines, identify bottlenecks, and optimize workflows autonomously.

Smart factories leverage IoT to create interconnected ecosystems where robots play a central role. For instance, mobile robots equipped with IoT sensors can track inventory levels, manage supply chains, and ensure timely delivery of materials. This integration reduces downtime and enhances productivity, making it a cornerstone of modern industrial strategies. The Huizhou Zhongkai High-tech Zone exemplifies this approach by utilizing robotics and IoT to optimize logistics and warehousing operations.

IoT also supports predictive maintenance. Robots equipped with IoT sensors can detect potential issues before they escalate, minimizing downtime and reducing maintenance costs. This proactive approach ensures that operations run smoothly, further enhancing the value of robotics in industrial settings.

"The integration of IoT with robotics marks the dawn of a new era in industrial automation," according to experts. This synergy drives efficiency, sustainability, and innovation across sectors.

Sustainability and Energy Efficiency in Robotics

Sustainability and energy efficiency have become critical priorities in industrial robotics. Companies increasingly seek solutions that align with environmental goals while maintaining operational efficiency. Robotics manufacturers now integrate energy-saving technologies and sustainable practices into their designs, addressing the growing demand for eco-friendly automation.

Energy-Efficient Robotics Design

Modern robotics systems incorporate energy-efficient components to minimize power consumption. Manufacturers use lightweight materials and advanced motors to reduce energy usage during operation. For example, collaborative robots (cobots) consume significantly less energy compared to traditional industrial robots due to their compact design and optimized power systems. This efficiency makes cobots an attractive option for businesses aiming to lower their carbon footprint.

Additionally, many robots now feature regenerative braking systems. These systems capture and reuse energy generated during deceleration, further reducing overall power consumption. In logistics and warehousing, mobile robots equipped with such technology enhance energy efficiency while maintaining high productivity levels.

Reducing Waste Through Precision

Robotics contributes to sustainability by improving precision in manufacturing processes. Robots perform tasks with unmatched accuracy, reducing material waste and minimizing defects. In industries like electronics and automotive manufacturing, this precision ensures optimal resource utilization. For instance, industrial robots can cut manufacturing costs by 20% to 60% by reducing production lead times and improving overall productivity.

"Precision in robotics not only enhances efficiency but also supports sustainable practices by minimizing waste," as noted by industry experts.

Supporting Renewable Energy Integration

Robotics plays a vital role in advancing renewable energy initiatives. Robots assist in the production of solar panels, wind turbines, and battery systems, ensuring consistent quality and faster production rates. In the Huizhou Zhongkai High-tech Zone, robotics solutions streamline logistics operations, supporting the efficient distribution of renewable energy components. This integration highlights how robotics contributes to the global transition toward cleaner energy sources.

Long-Term Cost Savings and Environmental Impact

Energy-efficient robotics solutions offer significant financial and environmental benefits. By reducing operational costs by up to 30%, these systems provide long-term savings for businesses. Lower energy consumption translates to reduced utility expenses, while sustainable practices enhance a company's reputation among environmentally conscious consumers.

Around 90% of businesses worldwide plan to adopt robotic automation by 2030, reflecting the growing recognition of its economic and ecological advantages. This widespread adoption underscores the importance of energy-efficient robotics in achieving both profitability and sustainability.

"Investing in energy-efficient robotics is not just a financial decision; it is a commitment to a sustainable future," according to industry leaders.

Future Outlook on Sustainable Robotics

The future of robotics lies in further advancements in energy efficiency and sustainability. Innovations such as AI-driven energy management systems and biodegradable robotic components are on the horizon. These developments will enable industries to meet environmental regulations while maintaining competitive advantages.

By prioritizing sustainability and energy efficiency, robotics continues to shape a greener and more efficient industrial landscape. Businesses adopting these technologies position themselves as leaders in the global movement toward sustainable automation.

Industrial automation robotics offers diverse solutions, each tailored to specific operational needs. Collaborative robots excel in adaptability and human interaction, while industrial robots dominate high-speed, repetitive tasks. Mobile robots and AGVs enhance mobility and logistics efficiency. Aligning these choices with business goals ensures optimal performance. Decision-makers should evaluate task requirements, safety, ROI, and scalability to select the most suitable system. Consulting experts and planning for future needs further strengthens this process. Robotics continues to redefine industries, paving the way for smarter, more efficient operations in the evolving industrial landscape.

See Also

Leading Figures Shaping The Global Intelligent Control Sector

Easily Reach EVE Energy At Mobile Device Production Hub

Exploring Huizhou Zhongkai's Role In Industry Innovation

Innovative Advances Within Huizhou Zhongkai High-tech Area

Zhongkai High-tech Zone's Growth: An Industrial Development Analysis

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271