Outsourcing Electronic Manufacturing: A Step-by-Step Guide

Outsourcing electronic manufacturing has become a strategic move for businesses aiming to stay competitive in a rapidly evolving market. By delegating production to specialized providers, companies can streamline operations and allocate resources to innovation and growth. The global electronic manufacturing services market, valued at $539.40 billion in 2023, is projected to exceed $1 trillion by 2033, reflecting its growing significance. This approach empowers businesses to access advanced technologies, reduce costs, and adapt to market demands efficiently, making it an essential strategy in industries like automotive and consumer electronics.

Key Takeaways

Outsourcing electronic manufacturing allows businesses to focus on innovation and growth by leveraging the expertise of specialized EMS providers.

Partnering with EMS providers can significantly reduce operational costs and enhance efficiency, enabling companies to allocate resources more effectively.

Access to cutting-edge technology and skilled professionals through EMS providers helps businesses stay competitive and meet evolving market demands.

Scalability and adaptability in production are key benefits of outsourcing, allowing companies to adjust production volumes based on market fluctuations.

Establishing clear communication and setting measurable expectations with EMS providers fosters strong partnerships and ensures quality control.

Conducting thorough due diligence when selecting EMS providers minimizes risks and enhances the likelihood of successful outsourcing outcomes.

Building long-term relationships with EMS providers promotes mutual growth, innovation, and consistent quality in production.

Understanding Outsourcing in Electronic Manufacturing

What Is Outsourcing in Electronic Manufacturing?

Outsourcing in electronic manufacturing refers to the practice where businesses delegate the production of electronic components or devices to specialized third-party providers. These providers, often known as Electronic Manufacturing Services (EMS) companies, handle various aspects of the manufacturing process, including design, assembly, testing, and logistics. This approach allows businesses to focus on their core strengths, such as innovation and market expansion, while leveraging the expertise and infrastructure of EMS providers.

By outsourcing, companies can reduce operational complexities and improve efficiency. For instance, EMS providers streamline production processes, ensuring high-quality output at a lower cost. This strategy has become increasingly popular in industries that demand precision and scalability, such as telecommunications, automotive, and consumer electronics. Businesses benefit from faster time-to-market and the ability to adapt to changing market demands without investing heavily in manufacturing facilities.

The Role and Importance of EMS Providers

EMS providers play a pivotal role in the electronics manufacturing industry. They offer a comprehensive range of services that help businesses navigate the challenges of modern production. These services include product design, prototyping, supply chain management, and final assembly. By partnering with EMS providers, companies gain access to cutting-edge technology and specialized expertise that would otherwise require significant investment.

Industry Expert from IMS Manufacturing highlights, "EMS providers are essential partners in the electronics manufacturing industry, offering a broad range of services that help businesses navigate the challenges of modern production and bring high-quality products to market efficiently and cost-effectively."

Additionally, EMS providers enable scalability, allowing businesses to adjust production volumes based on market demand. This flexibility is crucial for industries experiencing seasonal variations or fluctuating consumer preferences. For example, companies in Huizhou Zhongkai High-tech Zone have successfully leveraged EMS providers to meet global market demands while maintaining high-quality standards.

Outsourcing to EMS providers also reduces time-to-market, a critical factor in the competitive electronics sector. By offloading manufacturing complexities, businesses can focus on research, development, and marketing, driving innovation and growth.

Key Industries Leveraging Outsourced Electronic Manufacturing

Several industries rely heavily on outsourced electronic manufacturing to meet their production needs. These industries include:

Telecommunications: Companies in this sector outsource the production of communication devices and network equipment to EMS providers. This ensures high-quality products that meet stringent industry standards.

Automotive: The automotive industry depends on EMS providers for the production of electronic components like sensors, control units, and infotainment systems. This partnership supports the industry's push toward electric and autonomous vehicles.

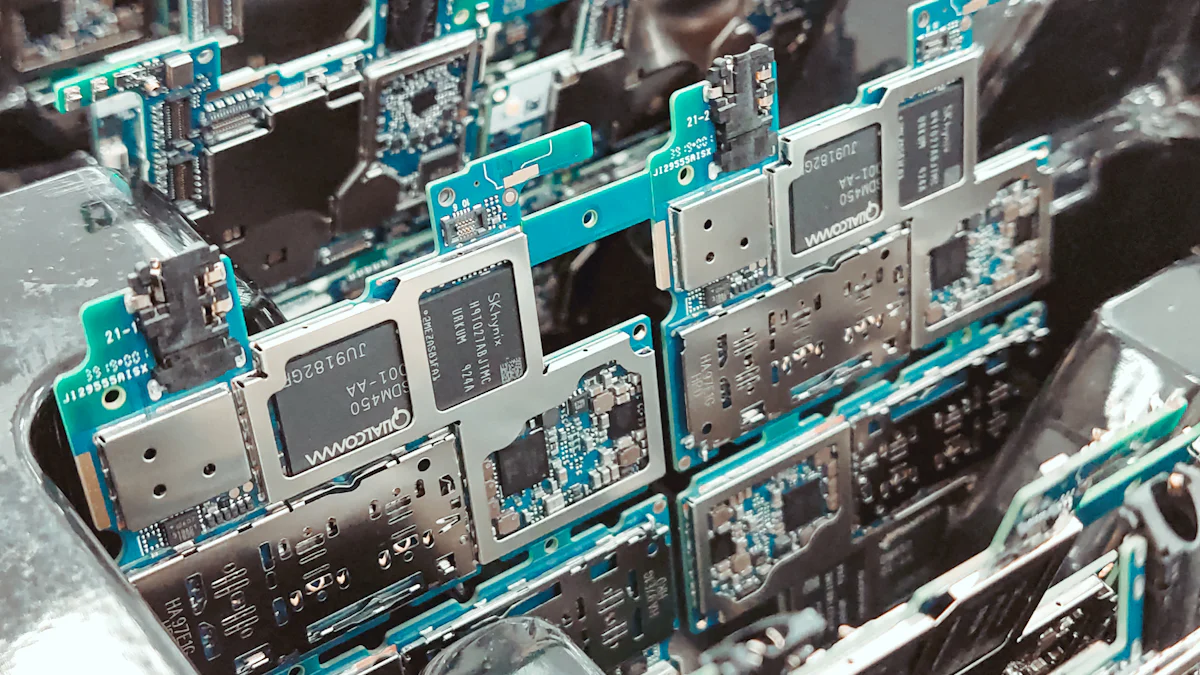

Consumer Electronics: EMS providers play a vital role in manufacturing smartphones, laptops, and other consumer gadgets. Their expertise ensures cost-effective production and rapid delivery to market.

Healthcare: Medical device manufacturers outsource the production of diagnostic equipment, monitoring devices, and wearable technology to EMS providers. This ensures compliance with regulatory standards and high-quality output.

Industry Expert from Precedence Research states, "EMS providers offer cost-effective and efficient solutions to various industries such as telecommunications, automotive, consumer electronics, and healthcare. Their expertise in electronic production ensures top-notch products and empowers OEMs to meet market demands with flexibility and innovation."

These industries benefit from the adaptability and efficiency that EMS providers bring to the table. By outsourcing electronic manufacturing, businesses in these sectors can focus on their core activities while ensuring high-quality, scalable production.

Benefits of Outsourcing Electronic Manufacturing

Cost Reduction and Operational Efficiency

Outsourcing electronic manufacturing offers businesses a significant opportunity to reduce costs and enhance operational efficiency. By partnering with external providers, companies can eliminate the need for maintaining expensive in-house production facilities. This approach reduces overhead expenses, such as utilities, equipment maintenance, and labor costs. For instance, outsourcing to regions with lower labor costs allows businesses to allocate resources more effectively.

Additionally, outsourcing minimizes the financial burden of hiring and training specialized staff. EMS providers already possess the expertise and infrastructure required for efficient production. This enables companies to focus on strategic activities like product development and market expansion. Businesses also benefit from economies of scale, as EMS providers handle large-scale production, further driving down costs.

Industry Insight: "Outsourcing enables businesses to cut down on operational expenses while boosting productivity through specialized knowledge and cost-efficient labor," according to market analysts.

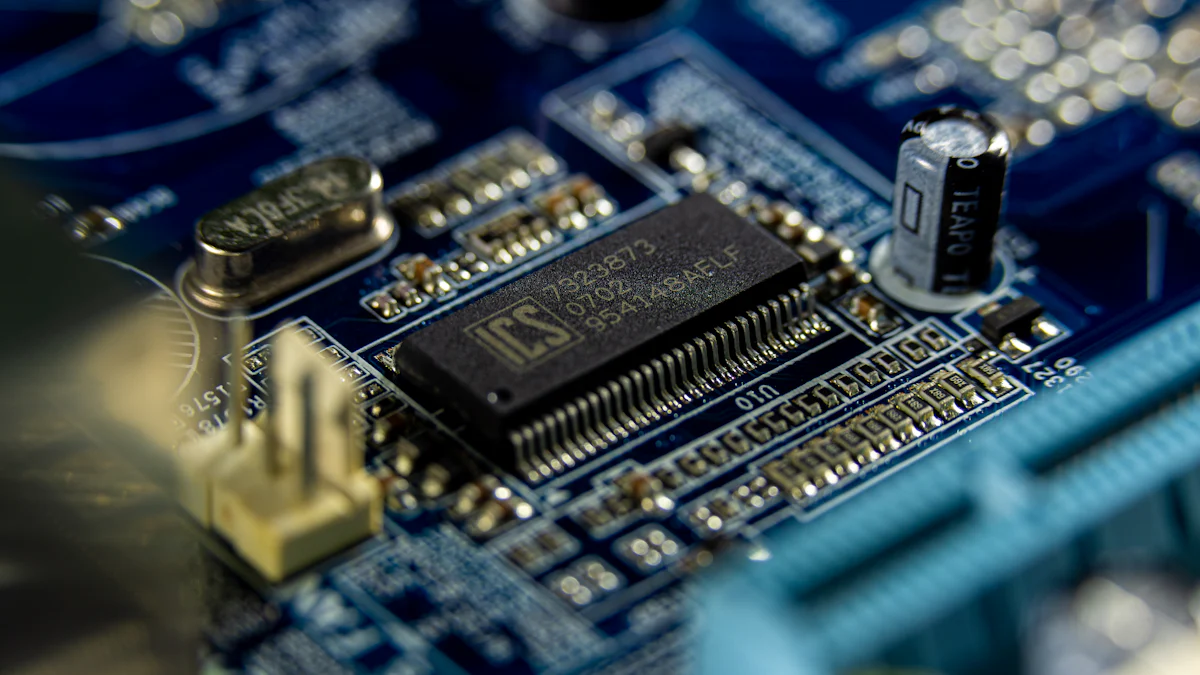

Access to Cutting-Edge Technology and Expertise

EMS providers invest heavily in advanced technologies and skilled professionals to stay competitive. By outsourcing, businesses gain access to these cutting-edge resources without incurring the high costs of acquiring them independently. This includes state-of-the-art manufacturing equipment, automated processes, and innovative design capabilities.

For example, companies in Huizhou Zhongkai High-tech Zone have leveraged EMS providers to integrate advanced technologies into their production lines. This collaboration ensures high-quality output and compliance with industry standards. Furthermore, EMS providers bring extensive experience across various industries, enabling them to address complex manufacturing challenges effectively.

Outsourcing also allows businesses to stay ahead of technological advancements. EMS providers continuously upgrade their capabilities to meet evolving market demands. This ensures that companies remain competitive and deliver innovative products to their customers.

Scalability and Adaptability in Production

Outsourcing electronic manufacturing provides businesses with the flexibility to scale production based on market demand. EMS providers offer adaptable solutions, allowing companies to increase or decrease production volumes without significant disruptions. This scalability is particularly valuable for industries experiencing seasonal fluctuations or rapid growth.

For instance, automotive and consumer electronics sectors often face varying demand levels. By outsourcing, these industries can adjust production efficiently, ensuring timely delivery of products. EMS providers also streamline supply chain management, reducing delays and optimizing inventory levels.

Moreover, outsourcing enhances adaptability by enabling businesses to respond quickly to changing market trends. Companies can introduce new products or modify existing ones without the constraints of in-house production limitations. This agility strengthens their competitive edge and fosters long-term growth.

Enhanced Focus on Core Business Functions

Outsourcing electronic manufacturing allows businesses to channel their resources toward core activities that drive growth and innovation. By delegating production tasks to specialized providers, companies can eliminate the distractions of managing complex manufacturing processes. This strategic shift enables organizations to prioritize areas such as research and development, marketing, and customer engagement.

For instance, businesses in the automotive and consumer electronics sectors have leveraged outsourcing to enhance their operational focus. Instead of allocating time and capital to maintaining production facilities, they concentrate on designing cutting-edge products and expanding market reach. This approach not only improves efficiency but also fosters a culture of innovation within the organization.

Industry Insight: "Outsourcing empowers companies to focus on their strengths, such as product development and strategic planning, while leaving manufacturing complexities to experts," according to market analysts.

Additionally, outsourcing reduces the burden of managing labor-intensive operations. Companies no longer need to oversee hiring, training, or retaining specialized staff for production. This shift minimizes administrative overhead and allows internal teams to dedicate their efforts to high-value tasks. For example, businesses in Huizhou Zhongkai High-tech Zone have successfully utilized outsourcing to streamline operations and achieve greater productivity.

Outsourcing also simplifies decision-making by reducing the number of variables involved in production management. With EMS providers handling logistics, quality control, and supply chain coordination, businesses can focus on strategic decisions that align with their long-term goals. This clarity in operations enhances overall organizational performance and ensures sustained growth in competitive markets.

Challenges of Outsourcing and Mitigation Strategies

Ensuring Quality Control and Standards

Maintaining consistent quality in outsourced electronic manufacturing presents a significant challenge. Businesses often rely on EMS providers to meet stringent quality benchmarks, but discrepancies can arise due to differences in processes or standards. Poor quality control can lead to defective products, customer dissatisfaction, and reputational damage.

To address this, companies must establish clear quality expectations from the outset. Defining measurable quality standards and incorporating them into contracts ensures accountability. Regular audits and inspections of the EMS provider's facilities help verify compliance with these standards. For example, businesses in Huizhou Zhongkai High-tech Zone have implemented robust quality assurance frameworks to maintain high production standards.

Additionally, leveraging advanced technologies like automated testing systems enhances quality control. EMS providers equipped with cutting-edge tools can identify defects early in the production process, reducing the risk of faulty products reaching the market. Effective communication between the business and the EMS provider further strengthens quality assurance efforts.

Pro Tip: "Collaborating with EMS providers that hold industry certifications, such as ISO 9001, ensures adherence to global quality standards."

Protecting Intellectual Property and Confidentiality

Outsourcing electronic manufacturing often involves sharing sensitive information, such as product designs and proprietary technologies. This creates a risk of intellectual property (IP) theft or unauthorized use. Protecting IP and maintaining confidentiality are critical for safeguarding a company's competitive edge.

Businesses can mitigate these risks by implementing robust legal agreements. Non-disclosure agreements (NDAs) and intellectual property clauses in contracts provide legal protection against unauthorized use or disclosure. Selecting EMS providers with a proven track record of safeguarding client data also minimizes risks.

Encryption and secure data transfer protocols further enhance confidentiality. Companies should limit access to sensitive information, sharing only what is necessary for production. Regularly monitoring the EMS provider's compliance with data protection measures ensures ongoing security.

Industry Insight: "Startups and SMEs must prioritize IP protection when outsourcing to drive value and innovation while safeguarding their unique ideas."

Building trust with the EMS provider is equally important. Establishing a strong partnership fosters mutual respect and commitment to protecting sensitive information. Businesses in Huizhou Zhongkai High-tech Zone have successfully collaborated with trusted EMS providers to ensure confidentiality and secure their intellectual assets.

Overcoming Communication and Cultural Differences

Effective communication is vital for successful outsourcing, yet it often becomes a challenge when working with EMS providers in different regions. Language barriers, time zone differences, and cultural nuances can lead to misunderstandings and delays. These issues can disrupt production schedules and impact overall efficiency.

To overcome these challenges, businesses should establish clear communication protocols. Designating a single point of contact within both organizations streamlines information flow and reduces confusion. Utilizing collaboration tools, such as project management software and video conferencing platforms, facilitates real-time communication across time zones.

Cultural training for both parties enhances mutual understanding and fosters a collaborative environment. Recognizing and respecting cultural differences builds stronger relationships and improves teamwork. For instance, companies outsourcing to providers in Huizhou Zhongkai High-tech Zone have benefited from cultural awareness initiatives that promote seamless collaboration.

Expert Advice: "Outsourcing allows businesses to delegate non-core functions and focus on what they do best, but effective communication remains key to achieving this goal."

Regular progress updates and performance reviews ensure alignment between the business and the EMS provider. Clear documentation of expectations, timelines, and deliverables minimizes the risk of miscommunication. By addressing communication and cultural challenges proactively, businesses can strengthen their outsourcing partnerships and achieve desired outcomes.

Managing Supply Chain and Logistics Risks

Outsourcing electronic manufacturing introduces complexities in supply chain and logistics management. Businesses must address these risks to ensure smooth operations and maintain product quality. Effective strategies can mitigate disruptions and enhance the reliability of outsourced production.

Identifying Potential Risks

Supply chain risks often stem from factors like material shortages, transportation delays, and geopolitical issues. For instance, disruptions in the availability of raw materials can halt production, leading to missed deadlines. Logistics challenges, such as inefficient shipping routes or customs delays, further complicate the process. Companies outsourcing to regions like Huizhou Zhongkai High-tech Zone must account for these variables to maintain consistent output.

Strategies to Mitigate Risks

Diversify Suppliers

Relying on a single supplier increases vulnerability to disruptions. Businesses should collaborate with multiple suppliers to ensure a steady flow of materials. Diversification reduces dependency and provides alternatives during unforeseen circumstances.Implement Robust Inventory Management

Maintaining optimal inventory levels minimizes the impact of supply chain disruptions. Businesses can adopt just-in-time (JIT) or safety stock strategies based on their production needs. EMS providers often assist in optimizing inventory to balance cost and availability.Leverage Technology for Visibility

Advanced tools like supply chain management software enhance transparency. These systems provide real-time updates on material availability, shipment status, and potential bottlenecks. Companies outsourcing to EMS providers in Huizhou Zhongkai High-tech Zone benefit from such technologies to monitor and streamline logistics.Establish Contingency Plans

Preparing for potential disruptions ensures quick recovery. Businesses should develop contingency plans that outline alternative suppliers, transportation routes, and production adjustments. Regularly reviewing and updating these plans strengthens resilience.

Building Strong Partnerships

Collaborating closely with EMS providers fosters trust and alignment. Clear communication about expectations, timelines, and responsibilities reduces misunderstandings. Regular performance reviews and feedback sessions help identify and address supply chain inefficiencies.

Industry Insight: "Strong partnerships with EMS providers enable businesses to navigate supply chain challenges effectively, ensuring timely delivery and consistent quality."

Monitoring and Continuous Improvement

Ongoing evaluation of supply chain performance identifies areas for improvement. Businesses should track key metrics like lead times, defect rates, and delivery accuracy. Implementing feedback loops with EMS providers promotes continuous optimization.

By proactively managing supply chain and logistics risks, companies can safeguard their operations and maintain competitive advantage. Outsourcing to trusted EMS providers, such as those in Huizhou Zhongkai High-tech Zone, ensures access to expertise and resources that enhance supply chain efficiency.

Step-by-Step Guide to Outsourcing Electronic Manufacturing

Define Your Business Needs and Objectives

The first step in outsourcing electronic manufacturing involves identifying the specific needs and objectives of your business. Companies must assess their production requirements, including volume, complexity, and timelines. This evaluation ensures clarity on what to expect from an EMS provider. Businesses should also define their long-term goals, such as cost reduction, improved efficiency, or access to advanced technologies.

A detailed analysis of internal capabilities helps determine which aspects of production to outsource. For example, companies in Huizhou Zhongkai High-tech Zone often focus on innovation and delegate manufacturing tasks to EMS providers. This approach allows them to allocate resources effectively and prioritize core competencies. Clear objectives act as a roadmap, guiding businesses toward successful outsourcing partnerships.

Pro Tip: "Documenting your business needs and aligning them with measurable objectives ensures a focused and efficient outsourcing process."

Research and Identify Potential EMS Providers

Once business needs are defined, the next step involves researching potential EMS providers. Companies should compile a list of providers that align with their industry and production requirements. Online directories, industry forums, and trade shows serve as valuable resources for identifying reputable EMS providers.

Businesses must evaluate the geographical location of providers. For instance, regions like Huizhou Zhongkai High-tech Zone offer access to advanced manufacturing facilities and skilled labor. Proximity to suppliers and markets can also influence the decision. Companies should prioritize providers with a proven track record in delivering high-quality electronic manufacturing services.

Industry Insight: "Selecting an EMS provider with expertise in your industry ensures compatibility and reduces the risk of production delays."

Evaluate Providers Based on Critical Factors

Thorough evaluation of potential EMS providers is crucial for making an informed decision. Businesses should assess providers based on several critical factors to ensure alignment with their needs.

Technical Expertise and Certifications

Technical expertise is a key consideration when selecting an EMS provider. Companies must verify the provider's capabilities in handling complex manufacturing processes. Certifications such as ISO 9001 and IPC standards indicate adherence to global quality benchmarks. Providers with advanced technical skills can address challenges effectively and deliver superior results.

Case Study: In 2019, a major IT company faced legal challenges due to outsourcing failures. This incident highlights the importance of partnering with certified and technically proficient EMS providers to avoid costly mistakes.

Industry-Specific Experience

Experience in the relevant industry enhances the provider's ability to meet specific requirements. For example, EMS providers specializing in automotive electronics understand the stringent quality standards and regulatory compliance needed in this sector. Businesses should request case studies or references to evaluate the provider's experience.

Providers in Huizhou Zhongkai High-tech Zone have demonstrated expertise across various industries, including telecommunications and consumer electronics. Their familiarity with industry-specific challenges ensures efficient and reliable production.

Financial Stability and Market Reputation

Financial stability reflects the provider's ability to sustain operations and invest in advanced technologies. Companies should review financial statements and market reputation to assess the provider's reliability. A financially stable EMS provider minimizes the risk of disruptions and ensures long-term collaboration.

Market reputation serves as an indicator of the provider's credibility. Businesses can gather feedback from existing clients or consult industry reviews to evaluate the provider's performance. Strong partnerships with reputable EMS providers enhance trust and foster successful outsourcing relationships.

Expert Advice: "Partnering with financially stable and reputable EMS providers reduces risks and ensures consistent quality in outsourced production."

Request Proposals and Conduct Thorough Due Diligence

Requesting proposals from potential EMS providers is a critical step in outsourcing electronic manufacturing. This process allows businesses to evaluate the capabilities, pricing, and services of various providers. Companies should prepare a detailed Request for Proposal (RFP) document that outlines their specific requirements. The RFP should include production volumes, quality standards, timelines, and any unique needs related to the project.

Once proposals are received, businesses must conduct thorough due diligence. This involves verifying the provider's credentials, certifications, and past performance. Site visits to the provider's facilities can offer valuable insights into their operational capabilities. For example, businesses outsourcing to providers in Huizhou Zhongkai High-tech Zone often prioritize on-site evaluations to ensure alignment with their quality expectations.

Legal and financial assessments are equally important. Reviewing the provider's financial stability minimizes risks associated with potential disruptions. Additionally, businesses should examine the provider's history of intellectual property protection. A failure to safeguard sensitive information can lead to legal complexities, as seen in the 2019 lawsuit faced by Accenture due to outsourcing failures. By conducting comprehensive due diligence, companies can mitigate risks and establish a strong foundation for collaboration.

Pro Tip: "Requesting detailed proposals and performing rigorous evaluations ensure that businesses select EMS providers capable of meeting their specific needs."

Negotiate Contracts and Set Clear Expectations

Negotiating contracts with EMS providers requires careful attention to detail. Businesses must ensure that all terms and conditions are clearly defined to avoid misunderstandings. Contracts should address key aspects such as pricing structures, payment terms, delivery schedules, and quality benchmarks.

Pricing Structures and Payment Terms

Pricing structures should reflect the scope and complexity of the project. Businesses can opt for fixed pricing, cost-plus models, or volume-based discounts, depending on their production needs. Payment terms must also be clearly outlined to prevent disputes. For instance, specifying milestones for partial payments ensures accountability and aligns with project progress.

Transparent pricing agreements protect both parties and foster trust. Companies outsourcing to regions like Huizhou Zhongkai High-tech Zone often benefit from competitive pricing due to the area's advanced manufacturing infrastructure and skilled workforce.

Delivery Schedules and Quality Benchmarks

Timely delivery is essential in electronic manufacturing. Contracts should include detailed delivery schedules with penalties for delays. Clear timelines help businesses plan their operations effectively and meet market demands. Quality benchmarks must also be defined to ensure consistent output. These benchmarks should align with industry standards and include measurable criteria for evaluation.

Industry Insight: "Setting clear expectations for delivery and quality ensures that EMS providers meet the required standards and timelines."

Establish Effective Communication and Collaboration Channels

Effective communication is the cornerstone of successful outsourcing partnerships. Businesses should establish structured communication channels to facilitate seamless collaboration with EMS providers. Designating dedicated points of contact within both organizations streamlines information flow and reduces the risk of miscommunication.

Regular meetings and progress updates keep both parties aligned. Utilizing project management tools and communication platforms enhances transparency and accountability. For example, businesses collaborating with providers in Huizhou Zhongkai High-tech Zone often rely on digital tools to bridge time zone differences and maintain real-time communication.

Cultural awareness also plays a vital role in fostering collaboration. Understanding and respecting cultural differences strengthen relationships and improve teamwork. Training sessions for both parties can enhance mutual understanding and create a more cohesive working environment.

Expert Advice: "Strong communication channels and cultural awareness are essential for building successful outsourcing partnerships."

Monitor Performance and Foster Long-Term Partnerships

Monitoring the performance of an EMS provider ensures consistent quality and operational efficiency. Businesses must establish clear metrics to evaluate the provider's output and adherence to agreed standards. Regular performance reviews help identify areas for improvement and maintain alignment with business objectives.

Key Performance Indicators (KPIs) for Monitoring

Defining measurable KPIs allows businesses to track the success of their outsourcing efforts. Common KPIs include:

Production Quality: Measuring defect rates and compliance with quality benchmarks ensures high standards.

Delivery Timelines: Tracking on-time delivery rates helps assess the provider's reliability.

Cost Efficiency: Evaluating cost savings compared to in-house production highlights the financial benefits of outsourcing.

Communication Effectiveness: Monitoring response times and issue resolution rates ensures smooth collaboration.

Industry Insight: "Regularly monitoring KPIs strengthens the relationship between businesses and EMS providers, fostering mutual growth and trust."

Businesses in regions like Huizhou Zhongkai High-tech Zone often use advanced analytics tools to track these metrics. These tools provide real-time insights, enabling proactive decision-making and swift issue resolution.

Conducting Regular Audits and Reviews

Periodic audits of the EMS provider's facilities and processes ensure compliance with contractual obligations. These audits verify that the provider adheres to quality standards, safety protocols, and industry regulations. For example, companies outsourcing to providers in Huizhou Zhongkai High-tech Zone often conduct on-site inspections to maintain high production standards.

Performance reviews should involve open discussions about achievements, challenges, and future goals. This collaborative approach fosters transparency and strengthens the partnership. Businesses can use these reviews to address concerns, set new targets, and explore opportunities for innovation.

Building Long-Term Partnerships

Establishing a long-term partnership with an EMS provider offers several advantages. A strong relationship promotes mutual understanding, trust, and commitment to shared goals. Businesses benefit from the provider's growing familiarity with their products, processes, and expectations.

To build a successful partnership, businesses should:

Invest in Relationship Management

Designating a dedicated team to manage the relationship ensures consistent communication and coordination. This team acts as a bridge between the business and the EMS provider, addressing issues promptly and fostering collaboration.Encourage Innovation

Supporting the EMS provider's efforts to adopt new technologies and improve processes benefits both parties. Businesses can share insights and feedback to drive innovation and enhance product quality.Recognize and Reward Performance

Acknowledging the provider's achievements motivates them to maintain high standards. Incentives such as performance bonuses or long-term contracts encourage continued excellence.

Historical Example: In 2019, Accenture faced legal challenges due to outsourcing failures, which damaged its reputation. This incident underscores the importance of fostering strong, reliable partnerships to avoid similar pitfalls.

Leveraging Regional Expertise

Regions like Huizhou Zhongkai High-tech Zone offer unique advantages for long-term partnerships. The area's advanced manufacturing infrastructure and skilled workforce make it an ideal location for outsourcing. Businesses collaborating with providers in this region benefit from access to cutting-edge technologies and a supportive ecosystem.

By monitoring performance and nurturing long-term partnerships, businesses can maximize the benefits of outsourcing electronic manufacturing. This approach ensures consistent quality, operational efficiency, and sustained growth in competitive markets.

Key Considerations for Successful Outsourcing

Conducting a Comprehensive Cost-Benefit Analysis

A thorough cost-benefit analysis forms the foundation of a successful outsourcing strategy. Businesses must evaluate the financial implications of outsourcing compared to in-house manufacturing. This process involves identifying all associated costs, including production, logistics, and potential risks, while weighing them against the expected benefits.

Outsourcing often reduces operational expenses by eliminating the need for maintaining in-house facilities. Companies save on labor, equipment, and overhead costs. For example, businesses in regions like Huizhou Zhongkai High-tech Zone leverage outsourcing to access cost-efficient labor and advanced manufacturing infrastructure. However, outsourcing may introduce additional expenses, such as transportation fees and vendor management costs. These factors must be accounted for to avoid unexpected financial burdens.

Pro Tip: "Include hidden costs, such as quality assurance and supply chain management, in the analysis to ensure accurate financial forecasting."

Comparing outsourcing with in-house manufacturing highlights key differences. Outsourcing may involve longer lead times due to external vendor schedules, while in-house production offers more direct control over timelines. Businesses must assess these trade-offs to determine the most cost-effective approach. A detailed cost-benefit analysis ensures informed decision-making and maximizes the return on investment.

Safeguarding Intellectual Property and Sensitive Data

Protecting intellectual property (IP) and sensitive data is critical when outsourcing electronic manufacturing. Sharing proprietary designs and technologies with external providers introduces risks of theft or unauthorized use. Businesses must implement robust measures to safeguard their competitive edge.

Legal agreements, such as non-disclosure agreements (NDAs) and intellectual property clauses, provide a strong foundation for data protection. These contracts outline the responsibilities of both parties and establish legal consequences for breaches. Selecting EMS providers with a proven track record of safeguarding client data further minimizes risks. For instance, companies outsourcing to providers in Huizhou Zhongkai High-tech Zone prioritize working with trusted partners to ensure confidentiality.

Industry Insight: "Encryption and secure data transfer protocols enhance the protection of sensitive information during outsourcing."

Limiting access to proprietary information strengthens security. Businesses should share only the necessary details required for production. Regular audits of the EMS provider's data protection practices ensure compliance with agreed standards. Building trust through transparent communication fosters a collaborative environment where both parties prioritize IP protection.

Ensuring Compliance with Industry Regulations

Compliance with industry regulations is essential for maintaining quality and avoiding legal complications in outsourced manufacturing. Different industries impose specific standards that businesses and EMS providers must adhere to. For example, the automotive sector requires strict compliance with safety and environmental regulations, while the healthcare industry mandates adherence to medical device standards.

Businesses must verify that their EMS provider holds relevant certifications, such as ISO 9001 or IPC standards. These certifications demonstrate the provider's commitment to quality and regulatory compliance. Companies outsourcing to regions like Huizhou Zhongkai High-tech Zone benefit from providers with extensive experience in meeting global standards.

Pro Tip: "Conduct regular audits to ensure the EMS provider consistently complies with industry regulations and quality benchmarks."

Clear documentation of compliance requirements in contracts ensures accountability. Businesses should also stay updated on regulatory changes to address new obligations promptly. Collaborating with EMS providers who prioritize compliance reduces risks and enhances the reliability of outsourced production. By ensuring adherence to industry regulations, businesses protect their reputation and maintain customer trust.

Building a Strong, Collaborative Relationship with the EMS Provider

Establishing a strong, collaborative relationship with an EMS provider ensures long-term success in outsourcing electronic manufacturing. Businesses must prioritize trust, communication, and mutual understanding to create a partnership that drives efficiency and innovation.

1. Foster Open and Transparent Communication

Clear and consistent communication forms the foundation of any successful partnership. Businesses should establish structured communication channels to ensure seamless information exchange. Designating dedicated points of contact within both organizations minimizes confusion and streamlines collaboration.

Regular updates and progress meetings help maintain alignment on project goals. Utilizing tools like project management software or video conferencing platforms enhances real-time communication. For example, companies working with providers in Huizhou Zhongkai High-tech Zone often rely on digital tools to bridge time zone differences and ensure smooth operations.

Pro Tip: "Frequent communication reduces misunderstandings and keeps both parties aligned on expectations and deliverables."

2. Align Goals and Expectations

Businesses must align their objectives with the capabilities of the EMS provider. Clearly defining production goals, quality benchmarks, and timelines ensures both parties work toward shared outcomes. Documenting these expectations in contracts provides a reference point for accountability.

For instance, companies outsourcing to regions like Huizhou Zhongkai High-tech Zone often outline specific quality standards and delivery schedules. This clarity helps avoid potential conflicts and ensures the provider meets the business's requirements.

3. Build Trust Through Mutual Respect

Trust is essential for fostering a collaborative relationship. Businesses should treat EMS providers as strategic partners rather than mere vendors. Recognizing the provider's expertise and contributions strengthens the partnership and encourages commitment to shared success.

Regular performance reviews and constructive feedback sessions promote transparency. Acknowledging achievements and addressing challenges together builds a sense of mutual respect. Companies in Huizhou Zhongkai High-tech Zone have demonstrated the value of trust by maintaining long-term partnerships with reliable EMS providers.

Industry Insight: "Strong partnerships thrive on trust and mutual respect, enabling businesses and providers to achieve shared goals effectively."

4. Encourage Innovation and Continuous Improvement

Collaborative relationships benefit from a focus on innovation. Businesses should encourage EMS providers to adopt new technologies and improve processes. Sharing insights and feedback fosters a culture of continuous improvement, enhancing product quality and operational efficiency.

For example, companies outsourcing to advanced manufacturing hubs like Huizhou Zhongkai High-tech Zone often collaborate with providers to integrate cutting-edge technologies. This approach ensures products remain competitive in dynamic markets.

5. Address Challenges Proactively

Challenges such as quality concerns or supply chain disruptions can strain relationships. Businesses must address these issues proactively to maintain collaboration. Establishing contingency plans and conducting regular audits ensures preparedness for potential risks.

Outsourcing may introduce risks like vendor reliability issues or longer lead times. Businesses should work closely with EMS providers to mitigate these challenges. For instance, diversifying suppliers and leveraging technology for supply chain visibility reduces disruptions.

Pro Tip: "Proactive problem-solving strengthens partnerships and ensures consistent performance in outsourced manufacturing."

6. Invest in Long-Term Collaboration

Long-term partnerships offer significant advantages, including improved efficiency and deeper understanding of business needs. Businesses should invest in relationship management by designating teams to oversee collaboration. Regularly reviewing goals and exploring new opportunities strengthens the partnership over time.

Recognizing the provider's efforts through incentives or extended contracts fosters loyalty. Companies outsourcing to Huizhou Zhongkai High-tech Zone often benefit from long-term collaborations that drive sustained growth and innovation.

By building a strong, collaborative relationship with an EMS provider, businesses can maximize the benefits of outsourcing. This approach ensures consistent quality, operational efficiency, and mutual success in competitive markets.

Outsourcing electronic manufacturing requires a structured approach to ensure success. Businesses must define their objectives, evaluate EMS providers thoroughly, and establish clear expectations. Aligning business needs with the right EMS partner, such as those in Huizhou Zhongkai High-tech Zone, enhances operational efficiency and fosters innovation.

Insight from IMS Manufacturing: "EMS providers now offer value-added services like design and logistics, enabling companies to access advanced skills and technology."

Approaching outsourcing as a strategic partnership unlocks long-term benefits. Companies can reduce costs, improve scalability, and focus on core competencies, driving sustainable growth in competitive markets.

See Also

Zhongkai High-tech Zone's Path to Elevating Electronics Sector

Unveiling Huizhou's Thriving Electronic Information Hub

Boosting Global Competitiveness Through Zhongkai High-tech Zone

Zhongkai High-tech Zone: Catalyst for Innovation in Electronics

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271