Revolutionary Ball Grid Array Tools Changing the Game

Ball grid array technology has become a cornerstone of modern electronics, enabling compact, high-performance designs for integrated circuits. Its innovative structure, which uses an array of solder balls to connect components to printed circuit boards, ensures reliability and efficiency. The global market for BGA tools reflects this importance, with sectors like rework stations and microcontroller sockets experiencing rapid growth. Advanced tools, such as precision soldering irons and X-ray inspection systems, are transforming how manufacturers handle BGA components. These advancements drive progress in industries ranging from consumer electronics to IoT devices.

Key Takeaways

Ball grid array technology is essential for creating compact and high-performance electronic devices, making it a cornerstone of modern electronics.

Advanced rework stations and precision soldering irons enhance the efficiency and success rate of BGA assembly and repair, ensuring reliable connections.

X-ray inspection systems provide non-destructive testing, allowing manufacturers to detect hidden defects in BGA components and maintain high quality standards.

Automated optical inspection (AOI) tools streamline the inspection process, balancing speed and accuracy to improve productivity in large-scale production.

AI-powered inspection systems revolutionize quality control by identifying defects with unmatched precision, significantly reducing human error.

Efficient thermal management tools are crucial for BGA soldering, preventing overheating and ensuring the reliability of increasingly compact electronic devices.

The trends of miniaturization and IoT integration are driving innovation in BGA tools, enabling the development of smarter and more compact devices.

Soldering and Rework Tools

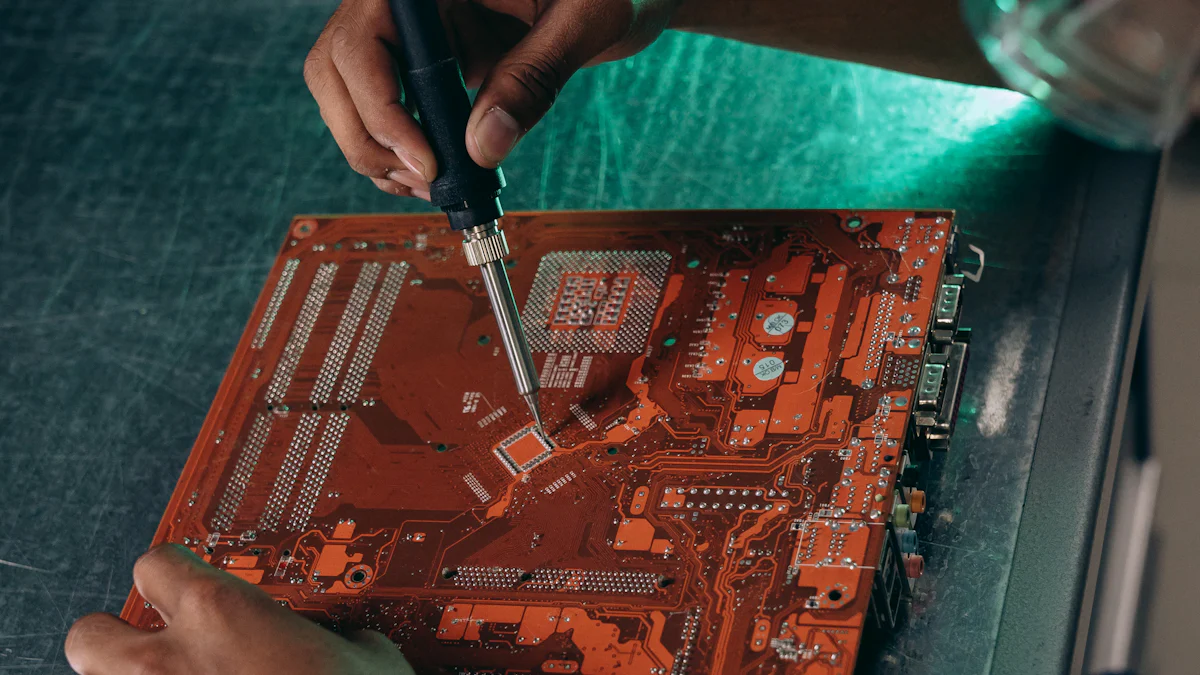

Soldering and rework tools play a pivotal role in the assembly and repair of ball grid array components. These tools ensure precision, reliability, and efficiency, which are essential for handling the intricate nature of BGA technology. The following subsections explore some of the most advanced tools revolutionizing this domain.

Advanced Rework Stations

Advanced rework stations have become indispensable for BGA assembly and repair. These stations combine cutting-edge heating systems with precise temperature control to handle delicate soldering tasks. For instance, the BGA Rework Station utilizes both bottom and top heaters to create controlled heating cycles, ensuring optimal soldering profiles for each component. This level of precision minimizes the risk of damage to sensitive parts during rework processes.

Another notable example is the QUICK 857DW+ Lead Free Hot Air Heat Gun Soldering Rework Station, which simplifies complex soldering tasks. Equipped with a high-performance hot air gun, it is particularly effective for mobile device repairs. Its ability to maintain consistent temperature levels makes it a trusted choice among technicians and electronics enthusiasts.

"Specialized tools with precise temperature control for delicate BGA and SMD work provide specific temperature profiles for each component to ensure successful rework."

These stations not only enhance efficiency but also improve the success rate of BGA repairs, making them a cornerstone of modern electronics manufacturing.

Precision Soldering Irons

Precision soldering irons are essential for achieving accurate and reliable connections in BGA components. The SS-350 BGA Soldering Station exemplifies this category with its advanced features. It offers precise temperature control, a high-performance soldering iron, and a built-in microscope magnifier for enhanced visibility. These features enable technicians to work with unparalleled accuracy, even on the smallest components.

Such tools are particularly valuable in industries where miniaturization is key, such as consumer electronics and IoT devices. By providing consistent performance and reducing the margin for error, precision soldering irons contribute significantly to the overall quality of BGA assemblies.

Hot Air Rework Systems

Hot air rework systems are another critical tool for handling ball grid array components. These systems use controlled streams of hot air to desolder and resolder components without causing damage to the surrounding areas. The QUICK 857DW+ Lead Free Hot Air Heat Gun Soldering Rework Station stands out in this category, offering professional-grade performance for tasks like phone repair and other intricate soldering jobs.

These systems are designed to simplify the rework process while maintaining high standards of precision. Their ability to handle lead-free soldering further aligns with modern environmental and safety standards. As a result, hot air rework systems have become a staple in both professional and hobbyist settings.

Inspection and Testing Tools

Inspection and testing tools ensure the quality and reliability of ball grid array components. These tools detect defects, verify solder joint integrity, and maintain high manufacturing standards. The following subsections highlight the most advanced solutions in this category.

X-ray Inspection Systems for Ball Grid Array Components

X-ray inspection systems provide unparalleled accuracy in evaluating ball grid array solder joints. These systems utilize automated X-ray inspection (AXI) technology to penetrate beneath the surface of BGAs, revealing hidden defects such as voids, misalignments, or insufficient solder. By offering a non-destructive testing method, X-ray systems allow manufacturers to maintain the integrity of components during inspection.

For example, AXI-based X-ray systems excel in identifying issues that traditional inspection methods cannot detect. Their ability to analyze internal structures ensures that even the most complex assemblies meet stringent quality standards. These systems have become indispensable in industries requiring high reliability, such as aerospace and medical electronics.

"X-ray inspection systems revolutionize BGA testing by providing detailed insights into solder joint integrity without compromising the component."

The precision and depth of analysis offered by X-ray systems make them a cornerstone of modern BGA inspection processes.

High-Resolution Microscopes for BGA Inspection

High-resolution microscopes play a critical role in visual inspections of ball grid array components. These tools magnify solder joints and other intricate features, enabling technicians to identify surface-level defects with exceptional clarity. Advanced models often include digital imaging capabilities, allowing for detailed documentation and analysis.

For instance, digital high-resolution microscopes enhance the inspection process by combining optical clarity with software integration. This combination enables users to capture images, measure dimensions, and generate reports efficiently. These microscopes are particularly valuable in applications where manual inspection remains essential, such as prototype development or small-scale production.

The use of high-resolution microscopes ensures that manufacturers can maintain consistent quality across all stages of production. Their ability to detect visible defects early in the process reduces the risk of costly rework or product failures.

Automated Optical Inspection (AOI) Tools

Automated optical inspection (AOI) tools offer a cost-effective solution for inspecting visible solder features on ball grid array components. These tools use advanced imaging technology to scan PCBs at high speeds, identifying defects such as missing solder balls, bridging, or misalignments. AOI systems provide rapid feedback, enabling manufacturers to address issues promptly.

The AOI tools for BGA inspection stand out for their efficiency and affordability. By automating the inspection process, these tools reduce the need for manual labor while maintaining high accuracy. Their ability to operate at high speeds makes them ideal for large-scale production environments.

"AOI tools streamline the inspection process, offering a balance between speed, accuracy, and cost-effectiveness."

The integration of AOI tools into manufacturing workflows enhances productivity and ensures that every BGA component meets the required specifications.

Alignment and Placement Tools

Alignment and placement tools are essential for ensuring the precise positioning of ball grid array components during assembly. These tools enhance accuracy, reduce errors, and improve the overall quality of electronic products. The following subsections explore two key technologies that have revolutionized this process.

Automated Pick-and-Place Machines for Ball Grid Array Assembly

Automated pick-and-place machines have become indispensable in modern electronics manufacturing. These machines streamline the assembly process by accurately positioning ball grid array components on printed circuit boards (PCBs). Their high-speed operation and precision reduce manual labor while maintaining consistent quality.

The RW1500 SMD BGA Rework System exemplifies the capabilities of advanced pick-and-place technology. It features motorized X, Y, and Z-axes for precise movement, ensuring accurate alignment and placement of BGAs. Its rapid infrared underheating and controlled hot air flow further enhance the soldering process. This system also incorporates advanced optical alignment, which minimizes errors and ensures repeatable results even with complex assemblies.

Another notable example is the Seamark SR820 BGA Rework Station, which combines precision and flexibility. Its built-in vacuum pen simplifies the handling of delicate components, allowing for effortless pickup and placement. The programmable profiles and intuitive interface make it user-friendly while maintaining high standards of accuracy. These features make the SR820 a preferred choice for both large-scale manufacturers and small-scale operations.

"Automated pick-and-place machines ensure precise alignment and placement, reducing defects and improving efficiency in BGA assembly."

By integrating these machines into production lines, manufacturers can achieve higher throughput and maintain the reliability of their products.

Alignment Jigs for Precise BGA Placement

Alignment jigs play a critical role in achieving precise placement of ball grid array components. These tools provide a stable framework for aligning BGAs with PCB pads, reducing the risk of misalignment and solder defects. Their simplicity and effectiveness make them a valuable addition to any assembly process.

High-quality alignment jigs often incorporate features like adjustable guides and locking mechanisms. These elements ensure that components remain securely in place during soldering. For instance, the RW1500 SMD BGA Rework System includes advanced optical alignment capabilities, which enhance the accuracy of placement. This feature is particularly beneficial when working with ultra-fine-pitch components or heat-sensitive materials.

The use of alignment jigs not only improves the precision of BGA placement but also reduces the likelihood of costly rework. By ensuring proper alignment from the outset, these tools contribute to the overall efficiency and reliability of the assembly process.

"Proper alignment during BGA placement is crucial for avoiding solder defects and ensuring long-term reliability."

Manufacturers who prioritize alignment and placement tools can achieve superior results, enhancing the performance and durability of their electronic products.

Software and Simulation Tools

Software and simulation tools have become indispensable in the design and troubleshooting of ball grid array components. These tools empower engineers to optimize layouts, predict potential issues, and ensure the reliability of electronic assemblies. By leveraging advanced algorithms and modeling techniques, they enhance efficiency and reduce errors in the development process.

BGA Design Software for PCB Layouts

BGA design software plays a critical role in creating precise printed circuit board (PCB) layouts. These tools allow engineers to design intricate patterns that accommodate the unique structure of ball grid array components. Features such as automated routing, layer management, and pad optimization ensure that the final design meets both functional and manufacturing requirements.

For instance, BGA Design and Simulation tools enable engineers to address challenges like low-cycle fatigue in electronic packaging. These tools provide insights into potential failure mechanisms, allowing designers to make informed decisions during the early stages of development. By simulating real-world conditions, they help optimize the placement of solder balls and ensure robust connections between components and PCBs.

"Physics simulations are critical for understanding the failure mechanisms of low-cycle fatigue in electronic packaging."

The integration of BGA design software into the development workflow reduces the likelihood of costly rework. It also ensures that the final product adheres to industry standards, enhancing its reliability and performance.

Simulation and Troubleshooting Software for Ball Grid Array Issues

Simulation and troubleshooting software offers a proactive approach to identifying and resolving issues in ball grid array assemblies. These tools simulate various scenarios, such as thermal stress, signal interference, and electromagnetic compatibility, to predict potential problems before they occur. By addressing these issues early, manufacturers can avoid delays and maintain high-quality standards.

PCB Simulation and Analysis Tools exemplify this category by providing a comprehensive suite of features. These tools support thermal and signal integrity (SI/PI) analysis, electromagnetic compatibility checks, and IBIS model-based simulations. Engineers use them to detect trouble spots, model electronic hardware, and ensure optimal performance under different operating conditions.

Key benefits of these tools include:

Faster enclosure design and layout optimization.

Early detection of thermal and electrical issues.

Enhanced signal integrity for complex digital circuits.

"In the course of hardware development, we use PCB simulation and analysis tools for faster enclosure design, trouble spot detection at early stages, and thermal and SI/PI analysis."

Simulation and troubleshooting software not only improves the efficiency of the design process but also enhances the reliability of the final product. By incorporating these tools, manufacturers can confidently address the complexities of ball grid array technology.

Emerging Innovations

The rapid evolution of technology has spurred groundbreaking innovations in ball grid array tools. These advancements address challenges in inspection, thermal management, and miniaturization, ensuring that manufacturers stay ahead in the competitive electronics industry. Below are some of the most transformative developments shaping the future of BGA technology.

AI-Powered Inspection Systems for BGA Technology

Artificial intelligence has revolutionized the inspection process for ball grid array components. AI-powered systems analyze solder joints with unmatched precision, identifying defects that traditional methods often miss. These systems utilize machine learning algorithms to detect patterns, predict potential failures, and enhance overall quality control.

For example, AI-driven inspection tools can process vast amounts of data in real time, enabling manufacturers to optimize production lines. By automating defect detection, these systems reduce human error and improve efficiency. Industries such as aerospace and medical electronics benefit significantly from this technology due to their stringent quality requirements.

"AI-powered inspection systems redefine quality control by combining speed, accuracy, and predictive analytics."

The integration of AI into inspection workflows ensures consistent results, making it an indispensable tool for modern electronics manufacturing.

Advanced Thermal Management Tools for BGA Soldering

Efficient thermal management has become a critical focus in BGA soldering. As electronic devices grow smaller and more powerful, managing heat effectively is essential to maintain performance and reliability. Advanced thermal management tools address this need by providing precise temperature control during soldering processes.

Innovative solutions, such as infrared-based heating systems, ensure uniform heat distribution across BGA components. These tools prevent overheating and minimize thermal stress, reducing the risk of damage to sensitive parts. The demand for such technologies continues to rise, driven by the increasing complexity of electronic assemblies.

"The market is witnessing a surge in demand for efficient cooling solutions in electronic devices, driven by the need for better thermal management."

By adopting advanced thermal management tools, manufacturers can enhance the durability and functionality of their products, meeting the expectations of modern consumers.

Trends in Miniaturization and IoT Integration in BGA Tools

Miniaturization has emerged as a defining trend in the electronics industry. Ball grid array tools now support the development of compact devices without compromising performance. This trend aligns with the growing demand for portable gadgets, wearables, and IoT-enabled devices.

Manufacturers leverage micro BGA packages to achieve smaller form factors while maintaining high-density connections. These packages enable the integration of IoT functionalities, allowing devices to communicate seamlessly. For instance, smart home systems and industrial automation rely on IoT-enabled components to deliver advanced capabilities.

"Miniaturization and IoT integration drive innovation in BGA tools, enabling the creation of smarter, more compact devices."

The combination of miniaturization and IoT integration ensures that BGA tools remain relevant in an increasingly connected world. These trends highlight the importance of continuous innovation in the field of electronics.

Ball grid array tools have revolutionized modern electronics by enhancing precision, efficiency, and reliability in manufacturing processes. From advanced rework stations to AI-powered inspection systems, these tools have reshaped industries by addressing complex challenges and driving innovation. The market's focus on sustainability and technological integration highlights the transformative impact of these advancements. Adopting cutting-edge solutions ensures manufacturers stay competitive in a rapidly evolving landscape. Exploring these tools empowers businesses to optimize operations and deliver superior products, meeting the demands of an increasingly connected world.

See Also

Zhongkai's Innovative Battery Technology Transformation

Discovering Zhongkai: Unexpected Advantages for Mobile Manufacturing

Innovative Developments in Huizhou Zhongkai Tech Hub

Assessing iFlight's Influence Within the Tech Zone

Transforming Semiconductor Displays: Zhongkai's Major Investment and Expansion

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271