How Smart Manufacturing Technologies Are Revolutionizing Huizhou Zhongkai High-tech Zone

Huizhou Zhongkai High-tech Zone stands as a beacon of innovation, driven by its commitment to research and development. This region has transformed into a hub for advanced manufacturing, leveraging cutting-edge technologies to redefine industrial processes. As the first national electronic information industrial base in China, it showcases a thriving ecosystem where smart manufacturing technologies play a pivotal role. Industry 4.0 initiatives, including artificial intelligence and IoT, empower businesses to automate operations and make data-driven decisions. These advancements not only enhance productivity but also position the zone as a leader in intelligent manufacturing.

Key Takeaways

Smart manufacturing technologies, including IoT, AI, and robotics, are transforming traditional manufacturing processes into highly efficient, automated systems.

The integration of IoT enables real-time data exchange, enhancing decision-making and operational efficiency, which leads to reduced maintenance costs and improved productivity.

AI applications in manufacturing drive automation and analytics, allowing businesses to optimize workflows and maintain high-quality standards through predictive analytics.

Robotics, particularly collaborative robots, enhance precision and efficiency in production, reducing human error and increasing workplace safety.

Digital twins provide manufacturers with virtual replicas of physical assets, enabling real-time optimization and minimizing risks during production changes.

Sustainability is a key focus, with smart technologies helping to minimize waste and energy consumption, aligning with the region's commitment to green manufacturing.

Overcoming barriers to adopting smart manufacturing requires workforce development, government support, and collaboration between public and private sectors.

Key Technologies in Smart Manufacturing

Internet of Things (IoT) for Connected Manufacturing

The Internet of Things (IoT) has become a cornerstone of smart manufacturing, enabling seamless connectivity across devices and systems. In manufacturing environments, IoT solutions support predictive maintenance by monitoring equipment performance and identifying potential issues before they lead to downtime. This proactive approach reduces maintenance costs and improves overall productivity.

In Huizhou Zhongkai High-tech Zone, IoT plays a pivotal role in transforming traditional factories into smart factories. By leveraging IoT-enabled systems, manufacturers gain better control over production processes and resource allocation. These advancements not only streamline operations but also contribute to the zone's reputation as a leader in smart manufacturing innovation.

Artificial Intelligence (AI) in Automation and Analytics

Artificial Intelligence (AI) drives automation and analytics in smart manufacturing, offering unparalleled efficiency and precision. AI-powered systems analyze vast amounts of data to identify patterns, optimize workflows, and predict outcomes. This capability allows manufacturers to make informed decisions and adapt to changing demands. Additionally, AI enhances quality control by detecting defects during production, ensuring consistent product standards.

In the Huizhou Zhongkai High-tech Zone, AI applications have revolutionized manufacturing processes. Businesses utilize AI-driven automation to reduce manual intervention and increase production speed. Predictive analytics, powered by AI, helps manufacturers anticipate market trends and align their strategies accordingly. These innovations position the zone as a hub for cutting-edge manufacturing technologies.

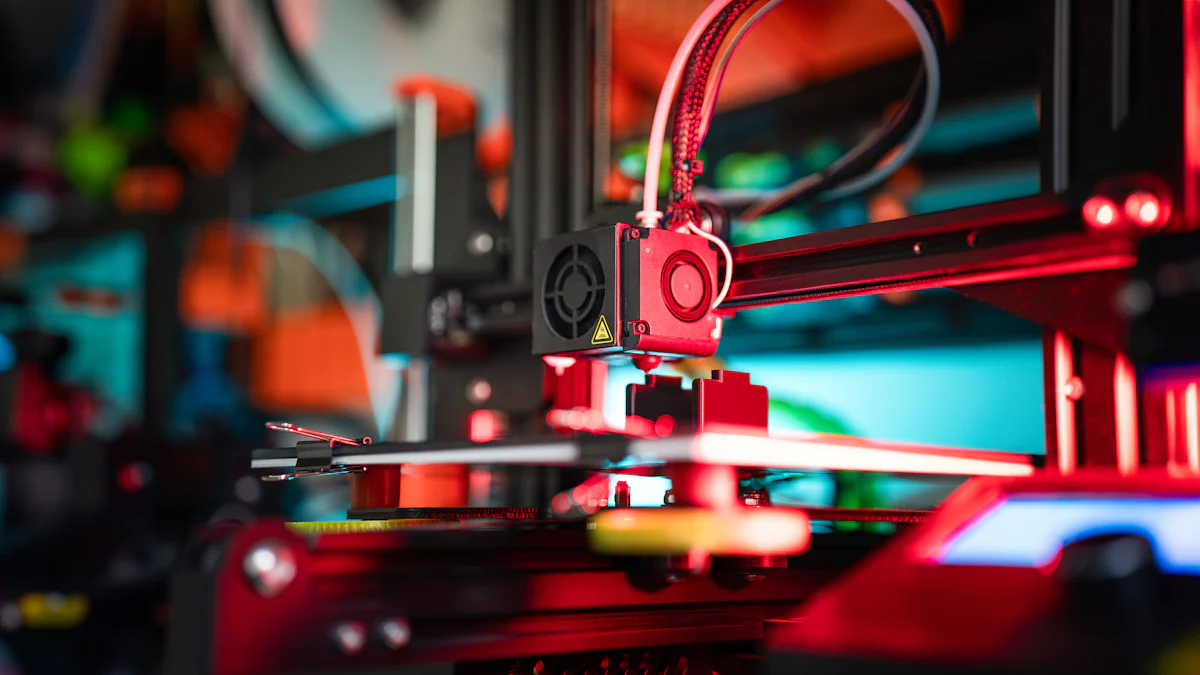

Robotics for Precision and Efficiency

Robotics has redefined precision and efficiency in manufacturing. Advanced robots perform repetitive and complex tasks with unmatched accuracy, reducing human error and increasing productivity. Collaborative robots, or cobots, work alongside human operators, enhancing workplace safety and efficiency. These robots can also integrate with IoT sensors and AI systems, creating intelligent production lines capable of adapting to real-time changes.

In the context of Huizhou Zhongkai High-tech Zone, robotics has become a key driver of industrial transformation. Factories in the zone deploy robotic systems to handle tasks ranging from assembly to packaging. This adoption of robotics not only boosts operational efficiency but also supports the zone's commitment to innovation and technological advancement.

Digital Twins for Real-Time Optimization

Digital twins have emerged as a transformative technology in smart manufacturing, offering real-time optimization and enhanced decision-making capabilities. A digital twin serves as a virtual replica of a physical asset, system, or process. It enables manufacturers to simulate, monitor, and analyze operations in real time. By leveraging this technology, businesses can identify inefficiencies, predict potential issues, and implement solutions without disrupting actual production.

In the Huizhou Zhongkai High-tech Zone, digital twins play a crucial role in advancing manufacturing processes. Factories utilize these virtual models to optimize production lines, ensuring seamless operations and minimal downtime. For example, digital twins allow manufacturers to test new workflows or equipment configurations virtually before applying them on the factory floor. This approach reduces risks and accelerates innovation.

"Key components of smart manufacturing include the use of additive manufacturing, advanced robotics, and the implementation of digital twins – virtual replicas of physical devices that enable real-time monitoring and analysis." – INCIT

The integration of digital twins with other technologies, such as IoT and AI, further enhances their capabilities. IoT sensors collect real-time data from machines, while AI algorithms analyze this data to provide actionable insights. Together, these technologies create a dynamic feedback loop that continuously improves efficiency and productivity. In the context of Huizhou Zhongkai High-tech Zone, this synergy fosters a highly adaptive and intelligent manufacturing environment.

Moreover, digital twins contribute to sustainability efforts by minimizing resource wastage and energy consumption. Manufacturers can simulate various scenarios to determine the most efficient use of materials and energy. This capability aligns with the zone's commitment to green manufacturing and sustainable development.

The adoption of digital twins in the Huizhou Zhongkai High-tech Zone underscores its position as a leader in smart manufacturing innovation. By embracing this cutting-edge technology, the region not only enhances operational efficiency but also sets a benchmark for intelligent and sustainable industrial practices.

Applications of Smart Manufacturing in Huizhou Zhongkai High-tech Zone

Transforming Local Industries with Smart Technologies

Smart manufacturing has significantly reshaped industries within the Huizhou Zhongkai High-tech Zone. By integrating advanced technologies such as IoT, AI, and robotics, local manufacturers have transitioned from traditional methods to highly efficient, automated systems. This transformation has enabled businesses to optimize production processes, reduce operational costs, and enhance product quality.

Robotics has further enhanced precision and efficiency, allowing companies to meet the growing demand for high-quality products. These advancements have not only improved productivity but also strengthened the competitiveness of industries within the zone.

Moreover, the adoption of digital twins has revolutionized factory operations. Manufacturers now use virtual replicas of physical assets to simulate and optimize workflows. This approach minimizes risks, accelerates innovation, and ensures sustainable resource utilization. As a result, industries in the Huizhou Zhongkai High-tech Zone have become more agile and adaptive, setting a benchmark for smart manufacturing practices.

Notable Smart Manufacturing Projects in the Zone

The Huizhou Zhongkai High-tech Zone has emerged as a hub for groundbreaking smart manufacturing projects. Several initiatives have demonstrated the transformative potential of advanced technologies in driving industrial growth and innovation.

Smart Factory Development: Local enterprises have established state-of-the-art smart factories equipped with IoT-enabled systems and AI-driven automation. These facilities leverage real-time data to optimize production lines, reduce downtime, and enhance operational efficiency.

Digital Twin Implementation: Many manufacturers in the zone have adopted digital twin technology to simulate production scenarios and test new workflows. This innovation has enabled businesses to identify inefficiencies, implement improvements, and achieve sustainable operations. According to Accenture Insights, digital twins accelerate progress toward autonomous operations by providing contextualized data for quicker decision-making.

Collaborative Robotics Integration: Factories have deployed collaborative robots, or cobots, to work alongside human operators. These robots handle repetitive tasks with precision, improving workplace safety and productivity. Their integration with IoT and AI systems has further enhanced their capabilities, creating intelligent production environments.

Green Manufacturing Initiatives: The zone has prioritized sustainability by incorporating smart technologies that minimize energy consumption and reduce waste. For instance, digital twins have been instrumental in optimizing resource utilization, aligning with the region's commitment to green manufacturing.

These projects highlight the innovative spirit of the Huizhou Zhongkai High-tech Zone. By embracing smart manufacturing technologies, the region has positioned itself as a leader in advanced industrial practices, paving the way for future growth and development.

Benefits of Smart Manufacturing for Huizhou Zhongkai High-tech Zone

Driving Economic Growth and Competitiveness

Smart manufacturing has become a catalyst for economic growth in the Huizhou Zhongkai High-tech Zone. By integrating advanced technologies such as IoT, AI, and robotics, local industries have enhanced their production capabilities and global competitiveness. Companies like TCL and Huawei exemplify this transformation. TCL's collaboration with the zone has enabled the integration of cutting-edge technologies into its manufacturing processes, boosting productivity and market reach. Similarly, Huawei's innovation hub within the zone has fostered technological advancements, creating a ripple effect that benefits the local economy. smart manufacturing technologies

The zone's modern industrial system, which includes electronic information, petrochemicals, and clean energy, has also experienced significant growth. For instance, the Daya Bay Petrochemical Zone has achieved a refining capacity of 22 million tons per year, ranking first in the country. This industrial strength, combined with smart manufacturing initiatives, has positioned the Huizhou Zhongkai High-tech Zone as a leader in advanced manufacturing. The second phase of a smart manufacturing base in the region, with a capacity to generate $1 billion in sales, further underscores its economic impact. modern industrial system

Advancing Sustainability and Green Manufacturing

Sustainability has become a cornerstone of smart manufacturing in the Huizhou Zhongkai High-tech Zone. By leveraging technologies like digital twins and IoT, manufacturers have optimized resource utilization and minimized waste. Digital twins, for example, allow factories to simulate production scenarios, ensuring efficient use of materials and energy. This approach aligns with the zone's commitment to green manufacturing and sustainable development.

The integration of clean energy solutions further enhances the zone's sustainability efforts. As an important production base for clean energy, the region has adopted smart technologies to reduce emissions and promote eco-friendly practices. Companies within the zone have embraced these initiatives, contributing to a greener industrial ecosystem. These efforts not only support environmental goals but also enhance the zone's reputation as a forward-thinking manufacturing hub.

Enhancing Operational Efficiency and Productivity

Operational efficiency has reached new heights in the Huizhou Zhongkai High-tech Zone through the adoption of smart manufacturing technologies. IoT-enabled systems provide real-time data on equipment performance, enabling predictive maintenance and reducing downtime. AI-driven analytics optimize workflows, ensuring seamless operations and higher productivity. Robotics, including collaborative robots, have further streamlined production processes by performing tasks with precision and speed.

The implementation of quality management systems, such as the IATF 16949 standard in local factories, reflects the zone's commitment to excellence. These systems ensure consistent product quality, enhancing customer satisfaction and market competitiveness. The combination of advanced technologies and stringent quality standards has transformed the zone into a benchmark for operational efficiency.

"Smart manufacturing technologies provide manufacturers with unprecedented real-time control over energy, productivity, and costs, leading to more sustainable operations." – Industry Insights

The Huizhou Zhongkai High-tech Zone continues to set new standards in intelligent manufacturing. By driving economic growth, advancing sustainability, and enhancing operational efficiency, the region solidifies its position as a global leader in smart manufacturing innovation.

Challenges and Strategies in Implementing Smart Manufacturing

Overcoming Barriers to Adoption

Implementing advanced manufacturing technologies often presents significant challenges. Many businesses in the Huizhou Zhongkai High-tech Zone face obstacles such as high initial investment costs, limited technical expertise, and resistance to change. These barriers can slow the adoption of innovative solutions and hinder progress toward intelligent manufacturing.

To address these issues, companies must prioritize workforce development. Training programs focused on upskilling employees in areas like IoT, AI, and robotics can bridge the knowledge gap. By equipping workers with the necessary skills, businesses can ensure a smoother transition to automated systems. Additionally, fostering a culture of innovation within organizations encourages employees to embrace new technologies and adapt to evolving industrial practices.

Another critical strategy involves leveraging government incentives and subsidies. Financial support can alleviate the burden of upfront costs, enabling small and medium-sized enterprises (SMEs) to invest in smart manufacturing technologies. Collaborative efforts between public and private sectors also play a vital role in overcoming adoption barriers. Partnerships with technology providers and research institutions can provide access to resources and expertise, accelerating the implementation process.

"The integration of advanced technologies requires not only financial investment but also a commitment to workforce development and collaboration." – Industry Insights

By addressing these challenges head-on, the Huizhou Zhongkai High-tech Zone can continue its journey toward becoming a global leader in intelligent manufacturing.

Policies and Collaborations Supporting Smart Manufacturing

Government policies and collaborative initiatives have been instrumental in driving the adoption of smart manufacturing in the Huizhou Zhongkai High-tech Zone. Local authorities have introduced a range of measures to support businesses in their digital transformation efforts. These policies include tax incentives, grants, and funding programs aimed at encouraging investment in advanced technologies.

The zone has also established innovation hubs and industrial parks to foster collaboration among stakeholders. These hubs serve as platforms for knowledge exchange, bringing together manufacturers, technology providers, and academic institutions. By facilitating partnerships, they enable the sharing of expertise and resources, which accelerates the development and deployment of smart manufacturing solutions.

Collaborative projects have further strengthened the region's industrial ecosystem. For instance, joint ventures between local enterprises and global technology leaders have resulted in the creation of state-of-the-art smart factories. These partnerships not only enhance the zone's technological capabilities but also boost employment opportunities. Studies suggest that smart manufacturing initiatives can increase the workforce by 2-4 times, contributing to economic growth.

Sustainability remains a key focus of these policies and collaborations. The integration of clean energy solutions and resource-efficient technologies aligns with the zone's commitment to green manufacturing. By promoting eco-friendly practices, the Huizhou Zhongkai High-tech Zone sets an example for other regions aiming to balance industrial growth with environmental responsibility.

Through strategic policies and collaborative efforts, the zone continues to pave the way for innovation and excellence in smart manufacturing.

Smart manufacturing technologies have profoundly transformed the Huizhou Zhongkai High-tech Zone, driving innovation and redefining industrial processes. The region has emerged as a leader in advanced manufacturing, supported by government policies that foster innovation and business growth. Companies like TCL have leveraged these technologies to enhance production capabilities, contributing to the zone's economic development. With ongoing advancements and a commitment to sustainability, the zone is poised to seize future opportunities, setting a global benchmark for intelligent manufacturing practices.

See Also

Innovative Advances Within Huizhou Zhongkai High-tech Zone

Exploring the Flourishing High-tech Hub of Huizhou Zhongkai

Fostering Creativity: The Future of Huizhou Zhongkai High-tech Zone

Opening Doors to Possibilities in Huizhou Zhongkai High-tech Zone

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271