Analyzing Surface Mount Technology in PCB Manufacturing

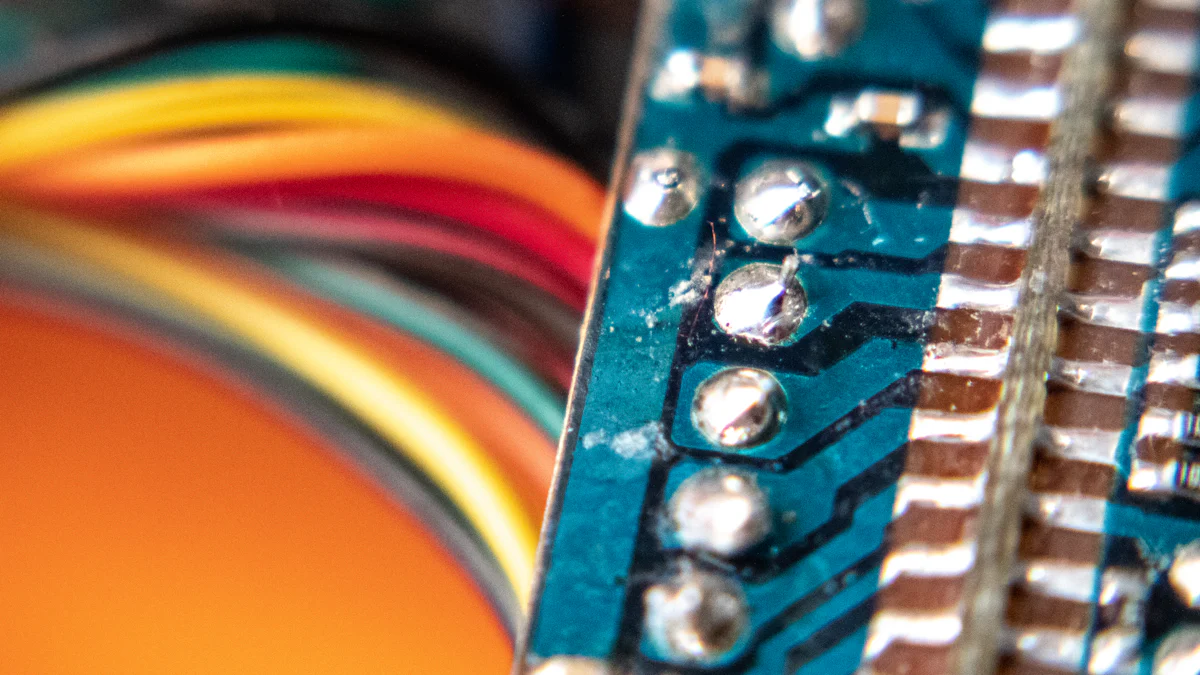

Surface mount technology has revolutionized the way printed circuit boards (PCBs) are manufactured. By eliminating the need for manual wire connections and drilling holes, this method has streamlined production processes and enabled automation. Manufacturers now achieve higher component density, reduced costs, and faster assembly times. Nearly all modern electronic devices rely on this technology, as it supports compact designs and enhances performance. The shift to surface mount technology has not only improved efficiency but also paved the way for innovative advancements in electronics manufacturing.

Key Takeaways

Surface Mount Technology (SMT) streamlines PCB manufacturing by eliminating the need for drilled holes, allowing for higher component density and more efficient use of space.

SMT significantly reduces production costs and assembly times through automation, making it ideal for high-volume manufacturing in industries like consumer electronics.

The compact design enabled by SMT supports the development of smaller, lighter electronic devices, enhancing performance and user experience.

While SMT excels in many applications, it may struggle in harsh environments; combining SMT with through-hole technology can create hybrid designs that leverage the strengths of both methods.

SMT is crucial in modern industries, including healthcare and automotive, where precision and reliability are paramount for advanced electronic systems.

Investing in SMT technology may require higher initial costs, but the long-term savings in labor and materials make it a financially sound choice for manufacturers.

Comparing Surface Mount Technology and Through-Hole Technology

Differences in Mounting Methods

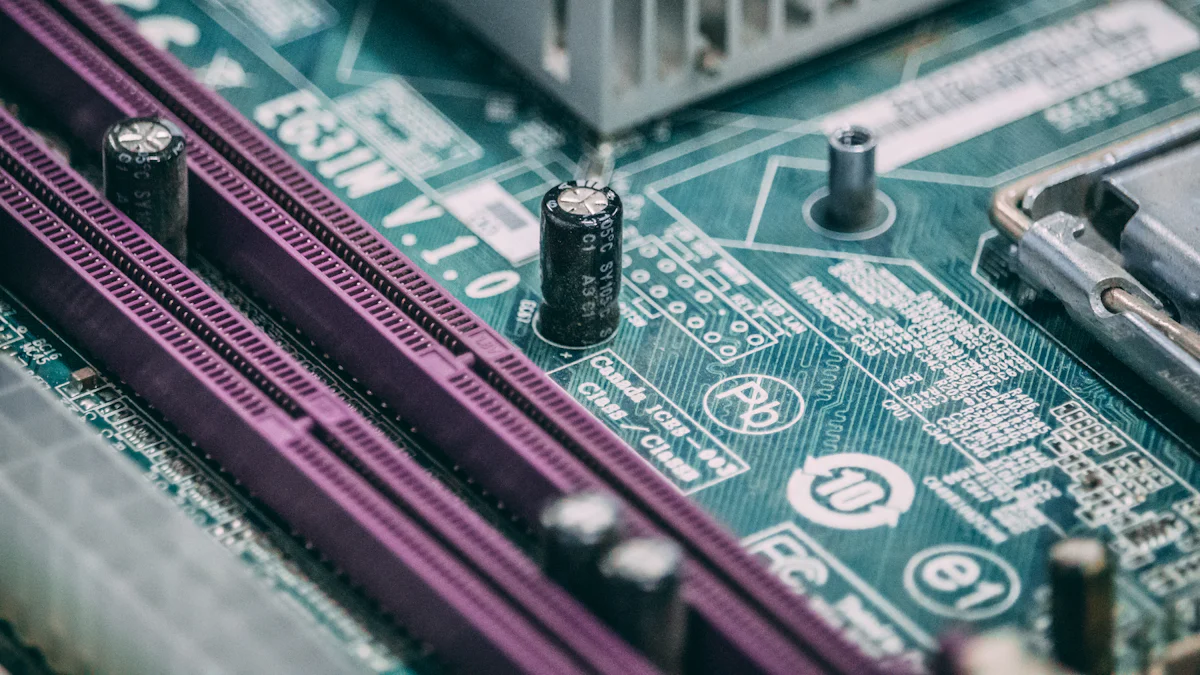

Surface mount technology (SMT) and through-hole technology differ significantly in their mounting methods. SMT involves placing components directly onto the surface of a printed circuit board (PCB), eliminating the need for drilled holes. This approach allows manufacturers to achieve higher component density and utilize PCB space more efficiently. In contrast, through-hole technology requires components to be inserted into pre-drilled holes and soldered on the opposite side of the board. This traditional method consumes more space and limits the complexity of circuit designs.

SMT supports the use of smaller, lighter components, enabling the creation of compact and lightweight electronic devices. Through-hole components, however, are bulkier and less suitable for miniaturized designs. The precision of SMT assembly also allows for fine-pitch components, which are essential for modern high-performance electronics. These differences highlight why SMT has become the preferred choice for advanced PCB manufacturing.

Cost and Efficiency Comparison

The cost and efficiency of SMT surpass those of through-hole technology in several ways. SMT production relies heavily on automation, which reduces labor costs and accelerates assembly times. Automated processes ensure consistent quality and minimize errors, making SMT ideal for high-volume production. Through-hole technology, on the other hand, often requires manual intervention, leading to higher labor costs and slower production rates.

SMT also reduces material costs by eliminating the need for lead forming and extensive wiring. Its ability to accommodate smaller components further contributes to cost savings. While the initial capital investment for SMT equipment may be higher, the long-term benefits in terms of efficiency and scalability outweigh the upfront expenses. Through-hole technology, with its higher manufacturing costs and slower processes, remains less competitive in modern electronics manufacturing.

Application Suitability in Various Environments

The suitability of SMT and through-hole technology varies depending on the application and operating environment. SMT excels in applications requiring compact designs, such as consumer electronics, wearable devices, and telecommunications equipment. Its ability to handle high-frequency signals and dissipate heat efficiently makes it a reliable choice for these industries.

Through-hole technology, however, retains its relevance in specific scenarios. It performs well in environments with extreme mechanical stress or high temperatures, such as aerospace and industrial applications. The stronger mechanical bond provided by through-hole components ensures durability under harsh conditions. Additionally, through-hole technology remains a practical option for prototyping and low-volume production due to its simpler setup requirements.

By understanding these distinctions, manufacturers can select the appropriate technology to meet the demands of their specific applications. SMT continues to dominate industries that prioritize miniaturization, efficiency, and automation, while through-hole technology serves niche markets requiring robust and durable solutions.

Benefits of Surface Mount Technology in PCB Manufacturing

Enhanced Automation and Scalability

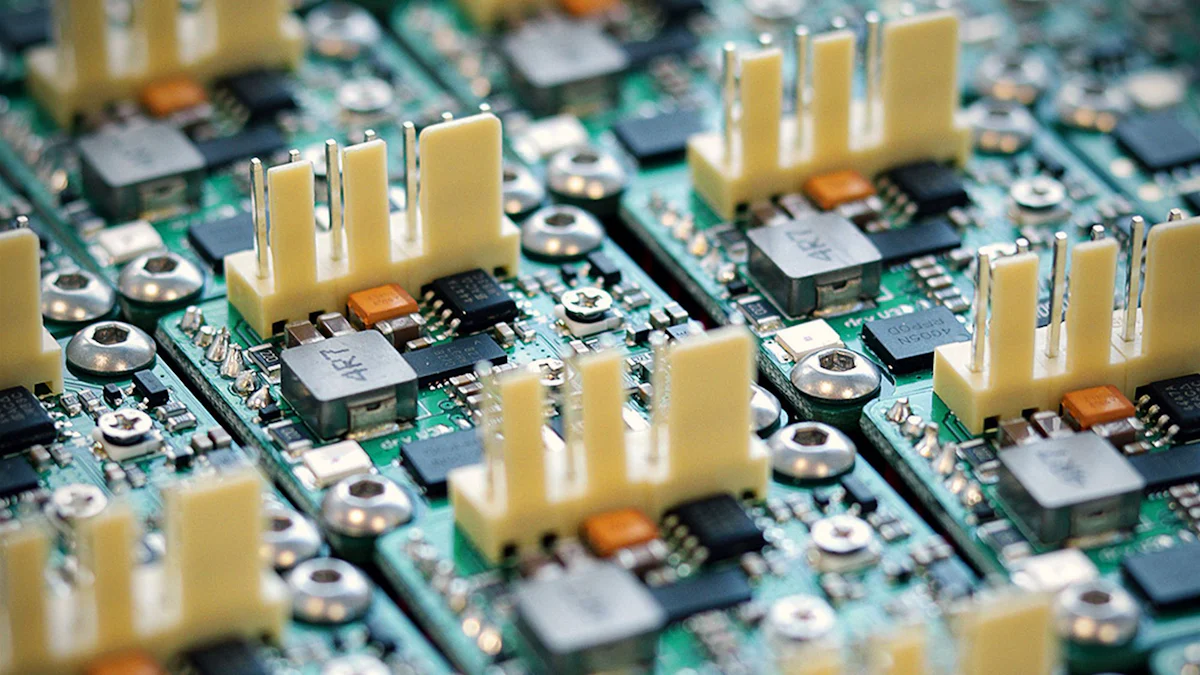

Surface mount technology has transformed PCB manufacturing by enabling a high degree of automation. Unlike through-hole technology, SMT eliminates the need for drilling, which significantly reduces production time. Automated machines can place thousands of surface-mounted devices (SMDs) per hour, compared to fewer than one thousand components with manual through-hole assembly. This efficiency allows manufacturers to scale production rapidly while maintaining consistent quality.

The scalability of SMT makes it ideal for industries requiring mass production, such as consumer electronics and telecommunications. A case study by PCBWay demonstrated that switching to SMT increased production speed by 25% and reduced costs by 30%. These improvements highlight how SMT supports both high-volume manufacturing and cost-effective operations. By leveraging automation, manufacturers can meet growing market demands without compromising on precision or reliability.

Cost Reduction and Material Efficiency

SMT offers substantial cost advantages in PCB manufacturing. The process minimizes material usage by eliminating the need for extensive wiring and lead forming. Smaller components used in SMT designs further contribute to cost savings, as they require less raw material. Additionally, the compact nature of SMT boards reduces shipping and storage expenses, making it a financially efficient choice for manufacturers.

Automation in SMT production also lowers labor costs. Machines handle most of the assembly process, reducing the need for manual intervention. This not only accelerates production but also ensures uniformity across batches. While the initial investment in SMT equipment may seem high, the long-term savings in labor and materials outweigh the upfront costs. For companies operating in competitive markets, SMT provides a clear path to cost-effective and scalable manufacturing.

Improved Electrical Performance and Design Flexibility

Surface mount technology enhances the electrical performance of PCBs by reducing resistance at connection points. Components in SMT designs sit closer to the board, improving heat dissipation and enabling higher circuit speeds. These characteristics make SMT particularly suitable for applications requiring high-frequency signals, such as telecommunications and automotive systems.

The design flexibility offered by SMT is another significant advantage. Smaller and lighter components allow engineers to create compact and intricate circuit layouts. Increased component density enables the integration of more functionalities into a single board, supporting the development of advanced electronic devices. SMT simplifies assembly processes, making it easier for manufacturers to meet industry standards and adapt to evolving technological requirements.

By combining improved performance with versatile design options, SMT empowers manufacturers to innovate and stay ahead in competitive industries. Its ability to support complex and high-performance circuits ensures its continued relevance in modern electronics manufacturing.

Limitations of Surface Mount Technology

Challenges in Harsh Operating Conditions

Surface mount technology (SMT) faces significant challenges when exposed to harsh operating conditions. Components mounted using SMT often struggle under extreme mechanical, environmental, or thermal stress. The compact design and high-density placement of surface-mounted devices (SMDs) make them more susceptible to damage in high-temperature environments. For example, SMDs can fail during prolonged exposure to elevated thermal conditions, which limits their application in industries like aerospace or heavy machinery.

The lack of robust mechanical bonds in SMT assemblies further complicates their use in demanding environments. Unlike through-hole technology, which provides stronger physical connections, SMT relies on solder joints that may weaken under vibration or mechanical stress. This limitation makes SMT less suitable for applications requiring high durability, such as industrial equipment or automotive systems operating in rugged terrains.

Combining SMT with through-hole technology can address some of these challenges. By leveraging the strengths of both methods, manufacturers can create hybrid designs that balance the compactness of SMT with the durability of through-hole components. This approach ensures reliability in extreme conditions while maintaining the advantages of modern PCB manufacturing.

Difficulties in Manual Rework and Repairs

Manual rework and repairs present another significant limitation of SMT. The miniaturized size of SMDs and their dense placement on PCBs make manual intervention highly complex. Technicians often require specialized tools and advanced skills to handle these components effectively. For instance, repairing or replacing a single component on a densely packed SMT board may demand precision equipment, such as microscopes and fine-tipped soldering irons.

Prototyping with SMT also poses challenges. High-density layouts leave little room for adjustments, making it difficult to add or replace components during the development phase. This limitation often necessitates professional expertise and expensive tools, increasing the overall cost and time required for prototyping. In contrast, through-hole technology offers greater flexibility for manual assembly and testing, making it a preferred choice for low-volume production or experimental designs.

The dense arrangement of components in SMT designs can further complicate debugging and troubleshooting. Insufficient space for detailed silkscreen markings on the PCB often hinders the identification of components during rework. This issue becomes particularly problematic in high-frequency or multi-layer boards, where even minor errors can disrupt functionality.

Despite these challenges, SMT remains a cornerstone of modern PCB manufacturing. Manufacturers operating in regions like Huizhou Zhongkai High-tech Zone continue to innovate, developing advanced tools and techniques to overcome these limitations. By addressing the difficulties associated with manual rework and repairs, the industry can further enhance the reliability and efficiency of SMT-based designs.

Applications of Surface Mount Technology in Modern Industries

Consumer Electronics and Wearable Devices

Surface mount technology has become a cornerstone in the production of consumer electronics and wearable devices. Manufacturers rely on its ability to support compact designs and high-density component placement. Smartphones, tablets, and smartwatches exemplify how SMT enables the integration of advanced functionalities into smaller, more portable devices. By utilizing SMT, companies achieve unprecedented levels of miniaturization while maintaining cost efficiency and performance.

The demand for wearable devices, such as fitness trackers and health monitors, continues to grow. SMT plays a critical role in meeting this demand by allowing the assembly of lightweight and durable components. These devices often require intricate circuit designs to accommodate sensors, wireless communication modules, and power management systems. SMT ensures that these features are seamlessly integrated, enhancing both functionality and user experience.

Expert Testimony:

"Surface Mount Technology facilitates the production of compact and feature-rich devices such as smartphones, tablets, and wearable technology, meeting consumer demand for smaller, more powerful gadgets."

This versatility makes SMT indispensable in the consumer electronics sector, where innovation and efficiency drive market success.

Healthcare Systems and Medical Devices

The healthcare industry benefits significantly from surface mount technology, particularly in the development of advanced medical devices. SMT enables the production of compact and precise diagnostic tools, patient monitoring systems, and implantable devices. These applications demand high reliability and accuracy, which SMT delivers through its automated assembly processes and superior electrical performance.

Medical devices often operate in critical environments where precision is paramount. SMT supports the integration of sensors, microcontrollers, and communication modules into compact designs, ensuring seamless operation. For example, implantable devices like pacemakers and insulin pumps rely on SMT to achieve the necessary miniaturization and reliability. Additionally, diagnostic equipment such as portable ultrasound machines and blood glucose monitors leverage SMT for enhanced functionality and portability.

Expert Testimony:

"Medical devices utilize SMT for precise diagnostic tools, patient monitoring systems, and implantable devices, supporting advancements in healthcare technology."

By enabling the creation of innovative and reliable medical solutions, SMT continues to advance healthcare technology and improve patient outcomes.

Automotive and Aerospace Innovations

The automotive and aerospace industries have embraced surface mount technology to meet the growing demand for advanced electronic systems. In the automotive sector, SMT supports the development of advanced driver-assistance systems (ADAS), infotainment systems, and vehicle control modules. These applications require high-performance components capable of withstanding harsh operating conditions. SMT ensures precision and reliability, making it an ideal choice for automotive electronics.

In aerospace, SMT plays a vital role in avionics, radar systems, and satellite communication equipment. These systems demand robust and lightweight designs to ensure optimal performance in extreme environments. SMT's ability to handle high-frequency components and dissipate heat efficiently makes it indispensable in these mission-critical applications.

Expert Testimony:

"Aerospace and defense sectors rely on SMT for robust and reliable electronics in avionics, radar systems, and satellite communication, crucial for mission-critical applications."

The adoption of SMT in these industries highlights its versatility and ability to meet stringent performance requirements. Companies in regions like Huizhou Zhongkai High-tech Zone continue to innovate, leveraging SMT to enhance the reliability and efficiency of automotive and aerospace electronics.

Surface mount technology (SMT) has redefined PCB manufacturing by enhancing efficiency, reducing costs, and enabling compact designs. Its ability to automate production and support high-density components has transformed industries reliant on advanced electronics. While SMT offers unparalleled advantages, it requires careful consideration of its limitations in specific environments.

Key Insight: "SMT drives innovation by enabling the creation of smaller, smarter, and more reliable devices across industries."

SMT continues to shape the future of electronics manufacturing. Companies in regions like Huizhou Zhongkai High-tech Zone leverage its benefits to meet evolving technological demands. Its role in advancing modern industries remains indispensable.

See Also

Transforming Semiconductor Displays: Zhongkai's Major Investment and Expansion

Discovering Zhongkai: Unexpected Advantages for Mobile Manufacturing

Maximizing Growth Through High-tech Zone Opportunities

Innovative Advances Emerging from Huizhou Zhongkai High-tech Zone

Zhongkai High-tech Zone: A Center for Cutting-edge Innovation

Zhongkai High tech Zone National foreign trade transformation and Upgradi Base(Electronic Information)Cloud Platform.

Address: Zhongkai High-tech Zone,Huizhou City ,Guangdong,China

E-mail: huizhoueii@163.com 13510001271@163.com

Tel: +86-0752-3279220 Mobile: +86-13510001271